- Home

- Companies

- Brentwood Industries, Inc.

- Products

- Model KFP 158 - Fills for Odor Control ...

Model KFP 158 -Fills for Odor Control and Ammonia Reduction

Exhaust Air Cleaning in Stables: Dust and ammonia are the substances to be cleaned from the waste air. Prescribed are cleaning efficiencies from 70-90% depending on where the sheds/stables are located. To efficiently and economically comply with this task, filling materials are needed which can be used in both counter and cross-flow applications (e.g. tunnel ventilation) in local waste air cleaning systems. The filling materials we have developed comply with all the requirements and have proved their operating efficiency in hundreds of installations.

- Effective and economical odor control and ammonia reduction

- Compliance with stringent environmental requirements

- Expert service

- High stability

- Long service life

- Low pressure lossEasy to clean

- High clogging resistance

- Highly efficient in substance transition range

We supply the ideal packing material for different plant requirements. Whether chemical exhaust air cleaning in cross-flow systems or biological exhaust air cleaning in counter-flow system, by co-operating with our customers, we are able to offer the most suitable packing material for any system concept.

Technical Data

- KFP 158

- Material: PP (Polypropylene)

- Specific surface (m²/m³): ~ 320

- Max. height (mm): 2.700

- Max. width (mm): 600

- Depth (mm): 150

- Channels: Cross-fluted

- HUMIPACKING is suited for cross-flow applications only.

- KFC, KVC fills are made of PVC

- KFP, KVP fills are made of PP (Polypropylene)

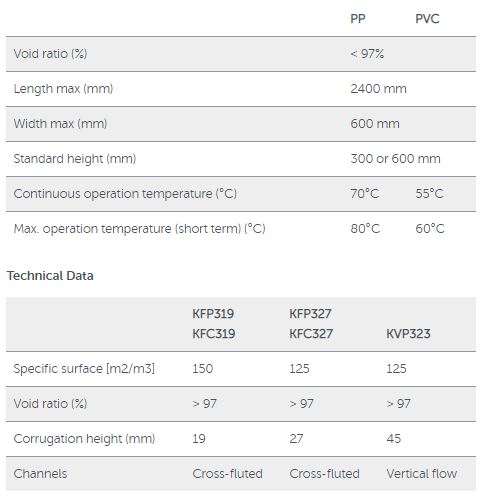

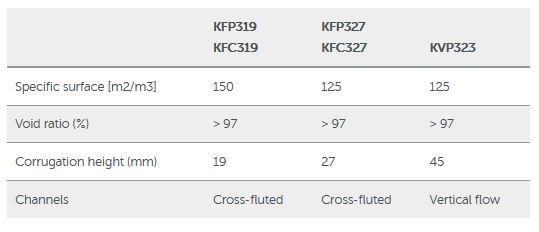

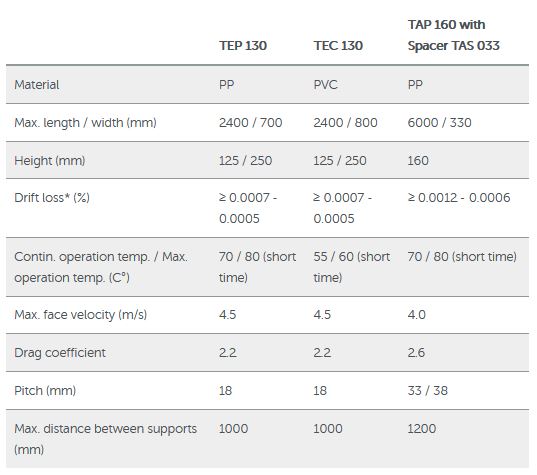

Technical Data

KFC, KVC fills are made of PVC

KFP, KVP fills are made of PP (Polypropylene)

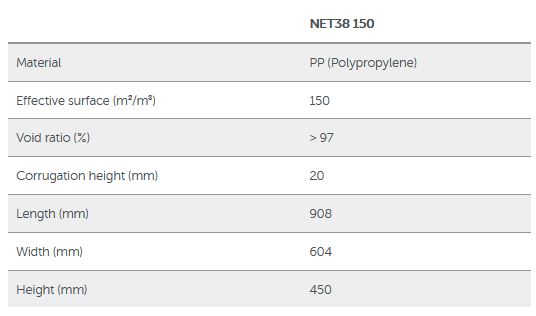

Technical Data

Technical Data

* Based on the CTI ATC-140 test method (Drift Test Code) and EUROVENT standard OM-14-2009. These limits are guidelines only. The performance of the drift eliminators is indicated by the ratio drift loss/water flow rate. The efficiency of droplet separation depends on constant air velocity and an absolutely tight assembly of drift eliminator elements.