Model MOV -Long Life Grease

In tests done at an independent laboratory these ‘MOV’ greases were about twice as good other products. There are four products currently available to meet specific requirements. These are `MOV Long Life`, `MOV Extra`, `MOV Syn` and >MOV Plus=. All use the same thickener, however, they have different base oil types and viscosities. >MOV Long Life= has a hydrotreated oil, `MOV Extra ` a more traditional but low viscosity mineral oil, `MOV Plus` a higher viscosity base oil and `MOV Syn` a synthetic oil. ‘MOV Plus’ is being phased out in favor of ‘MOV Long Life’ for nuclear applications and ‘MOV Extra’ for commercial applications. ‘MOV Syn’ is for applications requiring -40 °C performance.

These MOV greases also show much less degradation in accelerated age hardening tests. For this test, steel panels coated with a film of grease are subjected to temperatures of 150°C (302°F) for 96 hours. Traditional greases get hard or even flake off the panels.Plus, in ASTM tests for water washout, oxidation life and stability, they out performed many current products.

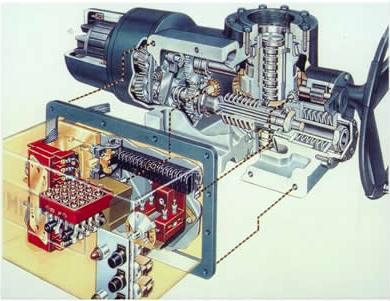

The Need

These products are especially suited to meet the needs of utilities and other users who want to reduce the problems associated with grease lubrication of valve stems and geared operators on both manual and motorized valves. More specifically, greases used for these applications can be subjected to hardening as a result of oil separation, oil evaporation, additive interaction, radiation and/or oxidation. This can result in wear, higher friction and/or increased downtime to maintain the valves or to reset the torque values. In addition, the performance of some greases can be seriously degraded by exposure to water and/or to some of the copper alloy materials used in this application.

The Product

A family of greases are available which are based on a proven calcium sulphonate complex thickener. Tests, such as those by ASTM (American Society for Testing and Materials) at independent laboratories and in-house show that these ‘MOV’ greases are better than current products. In addition, they are compatible with the calcium complex EP grease used previously.

Environmental Considerations

In addition, when compared to traditional extreme pressure greases, these MOV greases provide equal or better extreme pressure and anti-wear performance without requiring zinc additives. They also contain no added lead or chlorinated paraffins. Plus, the superior resistance to oil separation, to water washout, and to softening on working means that there should less age hardening and less oil separation. The potential for extended relubrication intervals and reduced wear can also result in less solid and liquid waste. Lastly, these MOV greases contain no artificial colours or solids for colouring.

MOV Long Life greases tested by EPRI for high temperature MOV`s and for bearings in Lube Notes for December 2006. Both did very well in comparison to the alternatives, especially when all the characteristics were considered.

Note Number 1, High Temperature Grease Evaluation: "The MOV LL result at the stem nut temperature of 85°C (185°F) warrants consideration in future testing. Not only does it appear that it will retain oil better, but it also has better oxidation stability and consistency retention (remaining a grade 2) than the other lubricants evaluated."

Note Number 3, Comparison of Roller Bearing Greases: "We believe that MOV LL will prove to be superior in antirust based on other, more rigorous tests. This feature is important in areas of high humidity near an ocean. Given that a bearing failure occurred due to a weld seize, there is a comfort in choosing MOV LL that has a significantly higher weld point and load-carrying ability."

Wear Resistant Characteristics

- Much better results than many of the current products in pin on disc testing.

- Maintains excellent pin on disc and four ball results even after heating.

- Consistent coefficient of friction in the pin on disc tests.

- Extreme pressure characteristics without zinc additives.

Stability

- More resistance to the age hardening than calcium complex greases.

- Excellent resistance to changes in consistency.

- Proven radiation resistant to at least 200 Mrads.

- Excellent corrosion protecting capabilities.

- Excellent resistance to oil separation and water washout.

- Only grease tested that passed the oven panel 96 hour test at 150C.

- Excellent resistance to both water (50%) and temperature in the roll stability test.

Safety and Environmental Issues

- Contains no artificial colouring agents.

- Contains no added lead or chlorinated substances.

- Manufactured in a “Responsible Care” member facility.

Compatibility

- Generally compatible with both calcium complex and lithium complex based greases.

Multipurpose

- MOV greases can be considered a multipurpose grease. As such they can also be very effectively utilized in other applications requiring such greases.

- Only grease said in EPRI Lube Notes to be suitable for main gearboxes, limit switches, and valve stems.

Quality Issues

- Based on proven technology that has been in use for over 10 years.

- Manufactured in an ISO 9002 registered plant.

- Produced by on of North America`s largest manufacturers of greases.