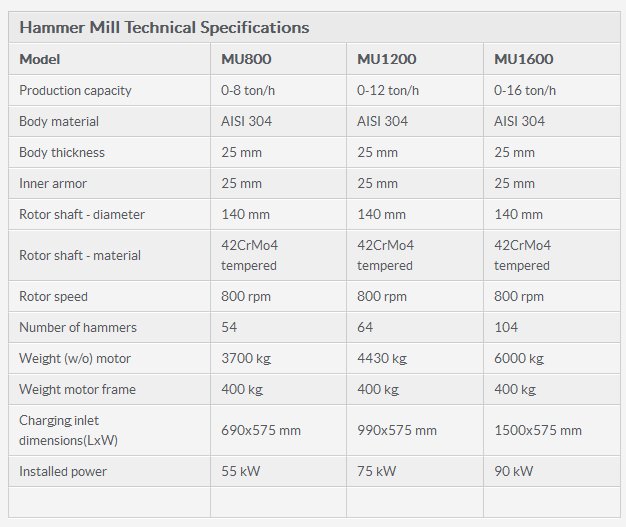

Model MU -Hammer Mill for Lead Battery Recycling

The hammer mill for lead battery recycling carries out the shredding of battery parts coming from the hammer crusher.

Small pieces are easier to transport and to treat, so they make the following operations of the lead battery breaking and separation process simpler.

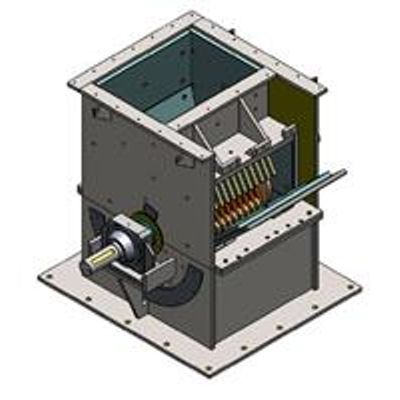

In the hammer mill for lead battery recycling the charge is supplied from above by means of a conveyor belt, the discharge takes place from the bottom and is transported by a screw conveyor. A grid fixed at the base of the hammer mill acts as a sieve for retaining larger pieces that have not been milled. The armor plates are fixed on the inner walls of the mill and have the function of protecting the mill from the violent impact of the battery pieces.

The armored front wall is hinged and can be easily opened. This configuration simplifies the operations of internal inspection and maintenance, such as the replacement of the hammers or the elements of the grid.

The mechanical and chemical stress which acts on the various parts of the hammer mill during the lead battery recycling requires an appropriate choice of the construction material: steel has been used for the realization of the hammers, as it is able to resist stress corrosion cracking. Furthermore, an adequate cycle of thermal treatments assures a higher impact resistance (resilience) and superficial hardness. The motor shaft is realized in quenched steel and designed to resist use and fatigue. The internal plates are realized in stainless steel. The shaft is driven by an electric motor and the transmission occurs by means of a belt and pulleys.

The motor of the hammer mill can be activated by the monitoring system developed on PC, both in manual and automatic mode. In particular, in manual mode start / stop is controlled by the user, while in automatic mode start / stop will be managed by the control software developed on PLC. In both cases, the boot is regulated by a soft-starter and the actual supply will only take place if the disconnector placed on board of the machine is not in the service position.

The hammer mill for lead battery recycling includes:

- Activation motor

- Supporting rotor of hammers

- Transmission belt

- Body of appropriate material

- Hammers able to crush batteries

- Supporting bearing of rotor