- Home

- Companies

- Naldi Ecologia S.r.l.

- Products

- Model Series SBR - Purification Plants

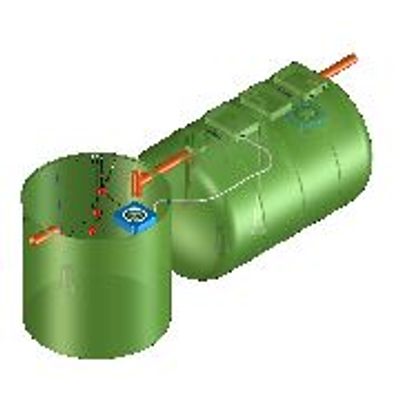

Model Series SBR -Purification Plants

The SBR system (sequential discontinuous reactor) consists of one or more parallel reactors, which provide for aeration, sedimentation, extraction of the effluent and sludge recirculation. Each reactor, after the filling phase, is conducted, by means of a PLC, in a (discontinuous) way for a predefined period and then the sewage, once clarified after the sedimentation phase, is discharged from the reactor. The reactor, moreover, allows all the basins of an activated sludge plant, including the sedimentation unit, to be united in a single tank, and therefore does not require any recirculation of the sludge.

This operational flexibility, which allows a rapid adaptation to the most varied operating requirements, is one of the main advantages of such systems. For small community plants, due to the considerable economic advantages (reduction of both construction and management costs compared to conventional plants), in many cases, traditional plants have been reconverted to active sludge or septic tanks in SBR systems.

Main features:

SBR systems for their operational flexibility and ease of management are particularly suitable for small treatment plants and for the reconversion of obsolete plants, as they have the following advantages compared to traditional systems:

- high resistance to hydraulic and organic overloads

- excellent retention capacity of the active biomass

- do not require biomass and nitrate recycling

- better oxygen transfer efficiency

- better Bulking control

- treatment flexibility by changing the times of the various phases

- lower energy cost of treatment