Model TDC 584 -IPA Conditioning Cabinet for Testing Air Filters

The harmonization of international testing standard ISO 16890-4 requires neutralization of tested filter element by Iso-propyl-alcohole (IPA) treatment. Therefore a suitable test cabinet for filter discharging is needed. The solution proposed in ISO 16890-4, chapter 7 requires a large amount of hazardous substance with approximately 1 l of liquid IPA, whereas particularly the handling of the trays filled with liquid IPA is risky. Furthermore large quantities of IPA saturated air enter the laboratory after opening the cabinet, which is a sanitary as well as a safety-related problem. It also requires an air extraction of the complete laboratory area.

- Fast and constant saturation of the air with IPA in a customizable saturation time

- Integrated suction and flushing of the chamber

- Minimal use of IPA (250ml per filter)

- Certification of security level by accredited certification bodies

- Conditioning of air filters according to ISO 16890-4 (for followed testing of the mechanical separation behaviour with the General Air Filter Test System ALF 114)

- Electrostatic neutralization of bag- and cartridge filters, filter bags and flat media

- Cabinet volume for filter element(s): 650 mm x 610 mm x 950 mm

- Auxiliary process time of filter conditioning Saturation Flushing 15 min, 20 min

- Dimensions 1000 mm x 1000 mm x 1800 mm

- Weight 250 kg

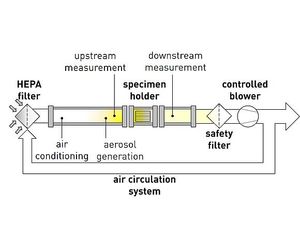

A defined volume flow rate is sucked through a HEPA intake filter, the attached test duct and the safety filter. The test system is composed of 6 sections: aerosol inlet, upstream measurement, specimen holder, downstream measurement, safety filter and flow rate measurement. The measurement sections are equipped with ports for the aerosol characterization and the determination of the pressure drop.

- Parameter title: Unit Value

- test flow rate: m³/h 800 ... 11 000

- test aerosol: DEHS, KCl, Ashrae, ISO 12103-A2 (AC fine), ISO 12103-A4 (AC coarse)

- dimension of test specimen: 610 × 610 (pocket and casette filters); diameter ≤ 400, lenght ≤ 1500 (filter catridges)

- differential pressure of test specimen: Pa max. 2000

- operating medium, gas/air - compressed air supply: bar min. 5 (17 m³/h)

- operating medium, water - water supply: bar min. 3

- power supply: 3 × 400 VAC, 125 A, 50 Hz

- air circulation: % 0 ... 100

- sensors, others: temperature, relative humidity, air pressure

- dimensions (w × h × d): m 4,6 × 1,7 × 14,0