- Home

- Companies

- Terberg Machines B.V.

- Products

- Model TLL1280 - Side/Rear Loading Lift

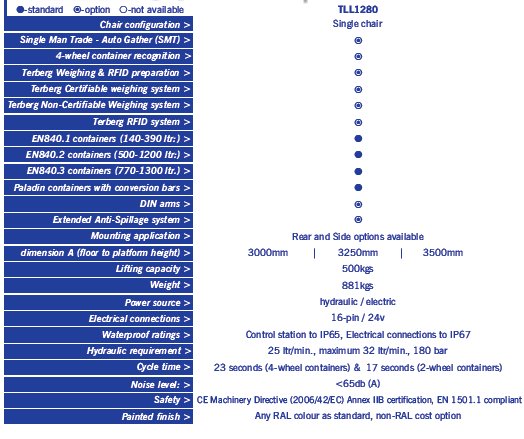

Model TLL1280 -Side/Rear Loading Lift

Kit version of the robust TL1280 lifter used on the Terberg Toploader, designed for mounting onto vehicle bodies to side and/or rear providing a binlift solution for up to 1280 litre wheeled bins that loads the body from the roof.

Integrated, compliant Emergency Stop system

The TLL1280 comes as standard with an emergency stop system that meets directive EN418:1992 for Safety of machinery. Integration with any existing vehicle stop system is made simple as the TLL1280 is provided with interface cabling ready for connection.

’Plug and Play’ electro-hydraulic installation

Offering ‘plug and play’ installation TLL1280 only requires hydraulic * pressure/return lines and a 24v DC electrical supply to allow hydroelectric integration with the host vehicle.

Control pendants allow safe distance

The wander lead control pendant allows the operator to stand well clear when raising & lowering containers clearly minimising the risk of injury. The pendant used represents a proven, robust control system that halts all bin lift movement when the buttons are released.

Available in several height options

The TLL1280 is available in three height options for side mounted and rear mounted applications giving you more flexibility for your choice of body size & design.

Controlled and safe lifting cycle

The lifter & roller track design employed is a tried & tested design, the lifter frame is fully constrained during the entire operation cycle and containers are secured with an uninterruptable clamping mechanism. This, together with a ‘damped’ start and finish to the lifting cycle and an ‘anti-shake’ feature offer safety & reduce mechanical fatigue to both containers and equipment.

Compatibility with EN 840 -1, 2 and 3 containers

TLL1280 offers a capable and flexible ‘bolt-on’ lifting solution that is flexible enough to cope with a wide range of containers from 140 litres.

Lifter raised warning

TLL1280 is supplied with an interface that allows the bodybuilder to provide an in-cab audio/visual alert device to warn the driver that the lifter is in the raised position when the park brake is released.

Trade container recognition option

Efficiency savings and safe operation are possible with the TLL1280`s trade container recognition option, an intelligent speed selection system automatically adjusts the lifting cycle time depending on the container size(s) loaded. Domestic containers are lifted more quickly than trade containers to save seconds that are vital to improving your efficiencies.

Single Man Trade (SMT) option

For ease of one man operation the TLL1280 is available with an SMT option, this feature enables automatic container ‘engagement’ before lift control is passed to the manual control pendant.

DIN arm option

A DIN arm option is available adding further flexibility, this allows the TLL1280 to lift trade containers fitted with DIN compliant ‘trunnions’. The DIN arm design incorporates a safe, gravity lock to ensure the container is held securely when lifting.

Optional extended Anti-Spillage system

To further reduce the likelihood of spillage when collecting materials such as glass, extended anti-spillage plates are available fitted from new or as a retro-fit item.

Compatible with Terberg dynamic weighing and RFID systems

The TLL1280 is designed to allow the integration Terberg’s dynamic weighing & identification systems. Consequently, the TLL1280 has a smooth operation designed to minimise ‘bin bounce’ and provides the vertical lifting ‘window’ required for accurate data recording.