Calgon Carbon - Model 12 -Modular Carbon Adsorption System

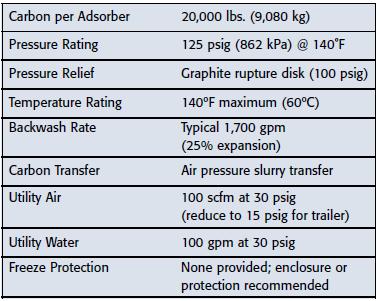

The Calgon Carbon Model 12 is an adsorption system designed for the removal of dissolved organic contaminants from liquids using granular activated carbon. The modular design concept allows the selection of options, additional accessories or alternate materials to best meet the requirements of the site and treatment application.

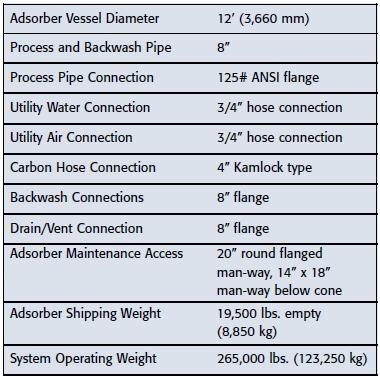

The MODEL 12 system is delivered as two adsorbers and a separate compact center piping network and interconnecting piping requiring minimal space and field assembly. The pre-engineered MODEL 12 design assures that adsorption system functions can be performed with the system as provided. The design has the benefit of Calgon Carbon`s extensive expertise and has been proven in numerous applications. The engineering package can be provided quickly and the system expedited through Calgon Carbon`s production capabilities.

The process piping network for the MODEL 12 accommodates operation of the adsorbers in parallel or series (with either adsorber placed in first stage). The piping can also isolate either adsorber from the flow. This permits carbon exchange or backwash operations to be performed on one adsorber without interrupting treatment. All valves and accessories are located at low elevations for ease of operation and maintenance.

The unique internal cone under-drain design provides for the efficient collection of treated water and the distribution of backwash water. The internal cone also insures efficient and complete discharge of spent carbon from the adsorber.

The MODEL 12 system is designed for use with Calgon Carbon`s closed loop carbon exchange service. Using specially designed carbon transport trailers, the spent carbon can be removed from the adsorber via a pressurized carbon-water slurry; and fresh carbon refilled in the same manner. This closed loop transfer is accomplished without exposure of personnel to either spent or fresh carbon. Calgon Carbon can also manage the disposition of the spent carbon; typically returned to Calgon Carbon for reac¬tivation avoiding the need for the site to arrange for disposal.

Carbon Adsorbers

- Carbon steel ASME code pressure vessels

- Internal vinyl ester lining (35 - 45 mil) where GAC contacts steel for potable water and most liquid applications

- Polypropylene slotted nozzles for water collection and backwash distribution

Standard Adsorption System Piping

- Schedule 40 carbon steel process piping with cast iron fittings

- Cast iron butterfly valves for process piping

- Full bore stainless steel ball valves for GAC fill and discharge

- PPL lined steel pipe for GAC discharge

- Pressure gages to measure pressure drop across system and each adsorber

- Rupture discs open to each vessel for pressure relief

Sysfem External Coating

- High solids epoxy paint system

Available Options

- System skid, shipped seperately, upon which system components can be assembled

- In-bed water sample collection probes