Paul Groth Mühlenbau GmbH & Co. KG

- Home

- Companies

- Paul Groth Mühlenbau GmbH & Co. KG

- Products

- Paul Groth - Modular Trough Chain ...

Paul Groth - Modular Trough Chain Conveyors

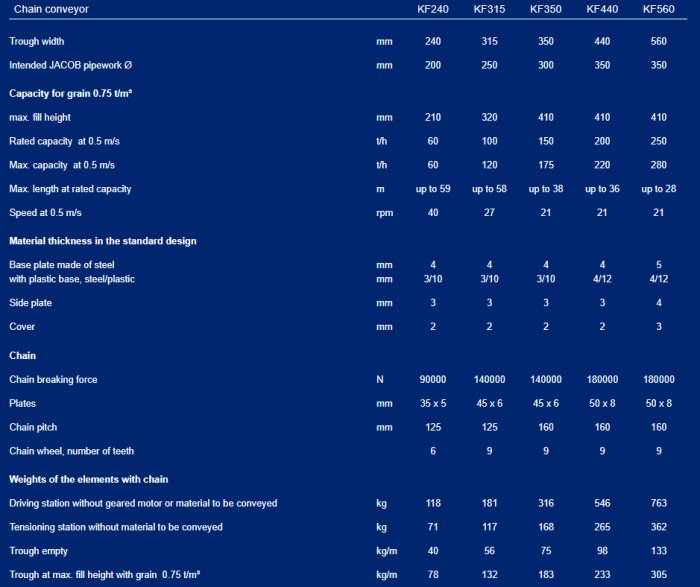

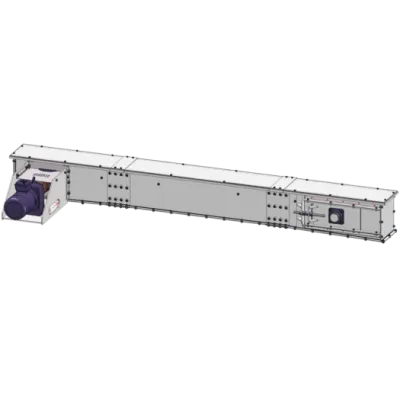

Paul Groth Mühlenbau GmbH & Co. KG specializes in the manufacture of versatile trough chain conveyors designed for transporting floury, grainy, and lumpy bulk materials. These conveyors are suitable for horizontal and slightly inclined conveyance, making them ideal for various industrial applications such as intake conveyors and silo discharge systems. The design starts with a modular system that can be adapted to specific product characteristics, installation conditions, and process requirements. Key technical features include material thickness adjustments in the standard design, various inlet options, and sensor integrations for overflow detection. The components boast robust construction elements such as chains per DIN 8165, rain covers for geared motors, and reinforced tension units capable for reversible transport direction. The chain conveyors are designed to be either varnished or hot-dip galvanized to improve durability and weather resistance, with options for either mineral or food-compatible synthetic gear oils in the system.Most popular related searches

chain conveyor

chain trough conveyor

trough conveyor

flexible coupling

conveyor system

integrity monitoring

roller bearing

Chain conveyors transport floury, grainy and lumpy bulk materials horizontally or on a slight upward incline. Chain conveyors can also be used as intake chain conveyors and for silo discharge.

Starting with our standard modular-system we adapt the chain conveyor to the product characteristics, the installation situation and the process requirements.

- Motor mounting platform with geared motor and flexible coupling

- Tensioning station and driving station, outside varnished and inside untreated, or hot-dip galvanised

- Troughs of strip-galvanised steel or outside varnished and inside untreated

- Return rollers made of plastic (standard for KF240, KF315 and KF350) or ball-bearing return rollers made of steel (standard for KF440 and KF560)

- Wear rails made of highly wear-resistant steel, e.g. Hardox, guide rail made of St52. With plastic bottom no wear rail

- Conveyor chain according to DIN 8165 with single bent-back plates