- Home

- Companies

- Galvanic Applied Sciences Inc.

- Products

- Monitek Turbidity - Suspended Solids & ...

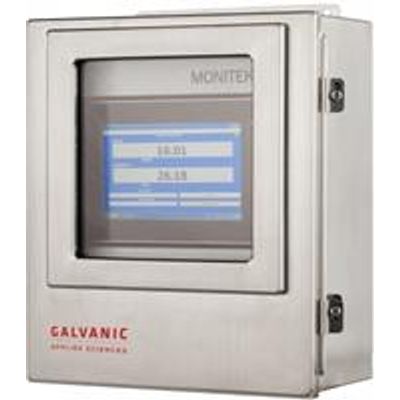

Monitek Turbidity - Suspended Solids & Color Monitors

Whether you’re brewing beer, optimizing critical pharmaceutical-manufacturing processes, or monitoring industrial wastewater for contamination, you need rugged, reliable, real-time results to optimize your processes and assure consistent quality and regulatory compliance. Galvanic delivers with its Monitek optical-technology-based turbidity, suspended solids, and color monitors, which delivers the highest performance-to-cost ratio of any in-line liquid process monitor on the market today.

The Utmost in Flexibility to Meet Your Toughest Analytical Challenges

Monitek’s two-component systems include modular, fit-for-purpose in-line sensors and submersible, insertion, and cell-density probes. These sensors pair with a messenger controller, which features intuitive multi-language graphical interface, setup via laptop PC or touchscreen, depending on model, automated cleaning cycles, and more. Unlike most turbidity, concentration, and color monitors, which can handle only one probe at a time, Monitek’s universal messenger controller can handle up to four discrete inputs, each individually controllable to monitor different streams or parameters, dramatically lowering the overall cost and complexity of system set up and operation.

- Extensive configuration of sensor options to meet application-specific requirements, e.g. line size, process connections, sensor material, pressure, temperature, gasket materials, optical path length, etc.

- Light-scattering and light-absorption techniques

- Standardized and custom-engineered sensor cells

- Compact, modular optics

- Price/performance advantage

- Easy set up and intuitive, multi-language graphical interface

- Wide range of communication options, including 4-20 mA, relay alarms, RS 232 to a computer, RS 485 Modus protocols and integral data logging

- One messenger controller can interface with any combination of sensors (turbidity, TSS, color), with up to four sensor inputs

- Each sensor has an independent interface channel on the messenger. Data is displayed and outputted individually with different units of measurement including NTU, JTU, AU, Hazen, EBC, ppm, g/l, % concentration, ASTM color, Saybolt color units, and others

- Messenger outputs can interface with customer DCS to provide valuable process information for process control, such as detection of filter breakthrough, upset process conditions, requirement for chemical dosing, etc.

- Wastewater treatment & chemical-dosing control via suspended-solids monitoring

- Wastewater treatment & chemical-dosing control via suspended-solids monitoring

- Copper-concentration monitoring during ore acid leaching process & refining

- Chloride contamination monitoring during copper (sulfate) refining

- Beer filtration monitoring

- Color of food products

- Filter breakthrough

- Filtration feedback

- Turbidity of food products

- Color of LNG & LPG

- APHA color in HCL production

- Filter breakthrough monitoring in chlor-alkali bleach process

- Heat exchanger leak detection

- Naphtha color / quality in crude distillation unit

- Oil in produced water

- Saybolt color scale in refined products

- Filtered water process

- Control plating operation – copper