- Home

- Companies

- Mechanical Solutions Inc. Testing & ...

- Products

- MSI - Virtual Testing of Electronic ...

MSI - Virtual Testing of Electronic Systems

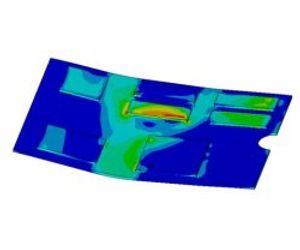

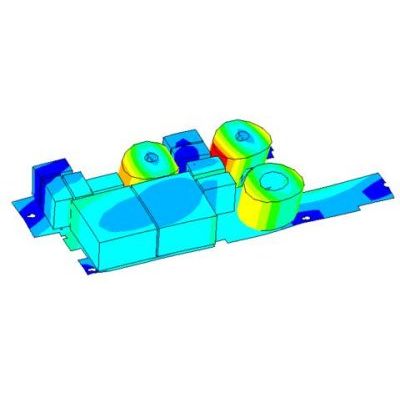

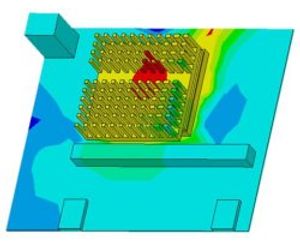

Mechanical Solutions, Inc. (MSI) performs “virtual testing” of electronic systems by applying advanced techniques of mechanical analysis.

The purpose of virtual testing for developers and manufacturers is:

General

- to condense development schedules

- trim expenses

- resolve reliability problems

- resolve manufacturing problems

Substantial experience together with state-of-the-art, multi-disciplinary analytical tools distinguish MSI from the competition.

When applied early in the design process, advanced Finite Element Analysis (FEA), and as-needed augmented with Computational Fluid Dynamics (CFD) analysis, more than pays for itself by eliminating the outdated, costly, and time consuming “trial and error testing” methodology of product development.

MSI has used advanced analytical tools to troubleshoot and to quickly resolve product issues that were associated with:

- assembly loads

- thermal anomalies

- premature component failure

- excessive noise

MSI specializes in solving challenging non-linear and multi-disciplinary problems, e.g. those which feature the combined interaction of fluids, thermal, and mechanical phenomena, in a timely and cost-effective manner.

Currently, the Reduction of Hazardous Substances in Electrical and Electronics Equipment (RoHS) legislation to eliminate lead-bearing solder provides an excellent example of the beneficial application of MSI’s “virtual testing” capabilities. Solder connects electronic components both electrically and mechanically. The absence of lead in solder can alter its mechanical characteristics such that failures occur in previously sound designs.

Manufacturers are challenged to balance the competing goals of rapid compliance with RoHS, no degradation in the mechanical performance of their updated products, and the cost-effective implementation of the RoHS-driven product modifications.

To assist these manufacturers, MSI can virtually evaluate the consequences of the substitution of RoHS-compliant materials in Printed Circuit Boards (PCBs) and other electronic product designs. Impending product failures can be identified. Hence the electronic product designs can be modified effectively in advance of the conductance of compliance / acceptance testing to ensure a smooth entry into a competitive marketplace.