Mud Puppy - Model 85 – RIG -Mud Recycler

Process and Clean up to 250 Gallons/Minute of Drill Mud. 400 Gallon Patented Mud Puppy Mud Tank.

- 2’ x 3’ Double Shaker Screen: Bottom 10 Mesh / Top 100 Mesh

- Two 5” Desander Cones

- 2” x 3” 118 Centrifugal Mud Pump set at 30 - 35 PSI

- 8” Sand Guzzler pick up pump

- Complete Hydraulic System

Save Time and Money

We know that time is money. With Mud Puppy Mud Recyclers, you are up and running in minutes, will never need a settling pit or be asked to shovel sand from the mud tank.

Our Mud Puppy line has been designed, engineered and built by leading professionals in the industry. Featuring a compact, lightweight and self-contained design, Mud Puppy offers top-of-the-line quality parts and units at prices that meet your budget.

Quick and Clean

The Mud Puppy Mud Recyclers are here to help you dispose of unwanted rock, sand and mud so that you can focus on getting the job done quicker and cleaner than the ever before. By using a Mud Puppy, you will dramatically reduce the wear and tear on the mud pump, drill string and other vital parts of the ground drill. In addition, having one of our mud recyclers will mean less water is needed on the job site and will result in cleaner mud for drilling.

Great Customer Service

With more than thirty years of unparalleled customer service, you will have the comfort knowing Mud Puppy will be there to service all of your crud clearing needs. We appreciate you considering Mud Puppy products and look forward to working with you.

COMPATIBILITY

A Mud Puppy is compatible with the following drilling jobs. Our process helps to save not only time on the job, but has been proven to increase the life of drill pump and plumbing equipment.

- Tunnel

- Horizontal Directional

- Geotechnical

- Oil

- Geothermal

- Environmental

- Water Wells

- Core

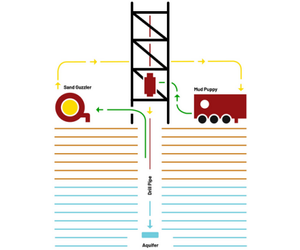

How Mud Puppy Works

A Mud Puppy works by filtering the drilling fluid and cuttings along the drill pipe, mud pit or mud pan and separates the rock, sand, clay and various unwanted fragments. After the initial filtration, smaller cuttings are further filtered through the tank and are pulled through the sand trap. From there, the cuttings are run through the desanding cones and processed on top of a finer screen located on the shaker bed. Finally, the mud is purified and now suitable to be sent back to the drilling rig.