- Home

- Companies

- Xinxiang Lifeierte Filter Corp., Ltd

- Products

- Lifeierte - Model LFS - Multi-Column ...

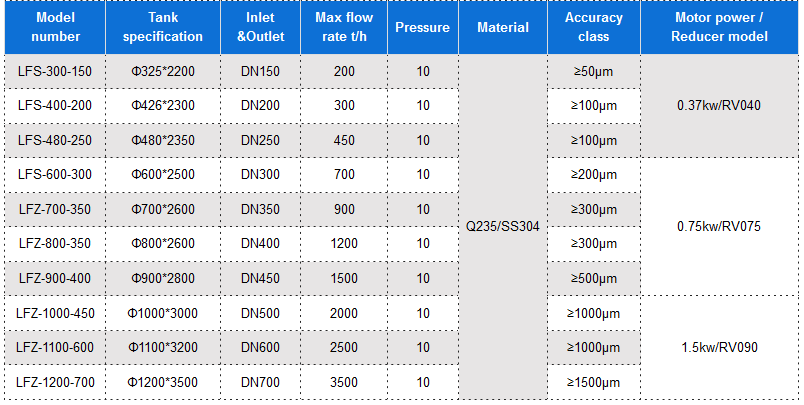

Lifeierte - Model LFS -Multi-Column Self-Cleaning Filter

The multi-column self-cleaning filter is an industrial automatic filter that offers a comprehensive range of uses and guarantees a pure and reliable filtered liquid. It is suitable for most of the standard applications of water filtration, in terms of capacity, accuracy and reliability, even under severe operating conditions.

- Applications: Electric power, reverse osmosis pre-stage, petrochemical, fine chemical, food and beverage, automotive, industrial, metallurgical, paper, pharmaceutical, microelectronics, environmental protection water treatment and other industries.

- Filtration media: water suspension, particulate matter, water dirt, bacteria and algae, rust, etc

Water from the entrance, first through the coarse filter to filter out the larger particles of impurities, and then reach the fine filter. In the filtering process, the fine screen gradually accumulates the dirt and impurities in the water, forming a filtering impurity layer, which accumulates on the inner side of the fine screen by the impurity layer, so a pressure difference is formed on the inner and outer sides of the fine screen. When the pressure difference of the filter reaches the preset value, it will start the automatic cleaning process, during which the clean water supply will flow continuously, the cleaning valve will open, the water pressure in the cleaning room and the dirt suction device will drop significantly, and through the pressure difference between the filter cartridge and the dirt suction tube, a suction force will be generated between the dirt suction tube and the cleaning room through the suction nozzle to form a dirt suction process. At the same time, the electric motor drives the suction tube to do spiral movement along the axial direction. The combination of the axial and rotational movements of the suction tube cleans the entire inner surface of the screen completely. The entire rinsing process takes only tens of seconds. The discharge valve closes at the end of the cleaning. The filter is ready for the next flushing cycle.

- Shell: Q235, SS304 Strainer: SS304l, SS316L

- Minimum backwash water pressure: 0.2 Mpa Discharge valve: cast iron, stainless steel

- Use: Water debris removal Seal ring: EPDM rubber

- System backwashing interval: 0-10h (adjustable depending on water quality) System backwashing sequence: unit by unit backwashing