Artel MVS - Multichannel Verification System

Accelerate assay optimization, simplify regulatory compliance, and ensure quality. Understand and manage the performance of your automated liquid handlers, multichannel pipettes, labware, operators, and more.

Compatible with virtually all automated liquid handling systems and multichannel handheld pipettes, the Artel MVS sits on a mobile workstation for portable rapid calibration, verifications and optimization of dispensed volumes with high precision and accuracy.

The MVS’s unique, dual-dye photometric measurements are robust against environmental influences and traceable to SI units to enable comparison across operators, protocols, equipment, and locations. Using the Calibrator Plate, Verification Plates, and an Artel-certified Plate Reader, the MVS supports an unbroken chain of traceability to national and international standards.

Dispense the Artel QualAssure solution and diluent into a verification plate & mix.

No need to prepare in-house dyes or generate a standard curve.

MVS measures absorbance values and generates volume measurements independently in each well of the verification plate.

No weighing is involved and environmental controls are not required.

The system automatically calculates accuracy and precision for individual volume values, for each tip or channel and provides summary statistics by well, row, and column.

Results are stored in the MVS Data Manager software, and reports are ready to print or export.

With the ability to quickly assess the accuracy and precision of multi-channel liquid transfers, whether they are dispensed by an automated liquid handler or a multi-channel pipette, you can enhance quality and productivity in so many applications. Calibration is just one example. Learn about other ways the MVS can support your work (and workflows) in the links below.

Key System Capabilities

- Verifies the accuracy and precision of all automated liquid handlers (1–384 dispensing tips) and handheld multichannel pipettes

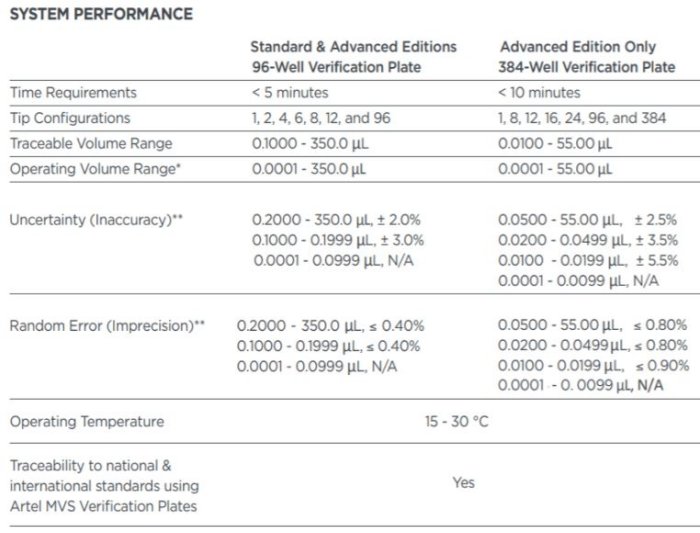

- Measures performance over a wide volume range of 0.0001 to 350 µL

- Measures aqueous and non-aqueous volume transfers, including dimethyl sulfoxide (DMSO) and PCR master mix-like (PCRMix)

- Obtains volume statistics tip-by-tip and well-by-well

- Provides highly accurate, standardized results, traceable to national and international standards

- Eliminates the need for rigorous environmental controls

- Simplifies verification and calibration—easy-to-use for technicians of any skill level

- Results traceable to national (NIST) and international (SI) standards

- Complies with the ratiometric photometric test method of ISO/IWA 15:2015

Flexible Applications

- Assessment of step-wise dilution accuracy

- Seamless integration with liquid handlers

- Facilitating of scale-up and method transfer

- Developing, troubleshooting, and validating assays, methods, and SOPs

- Ensuring reproducibility

- Site acceptance testing and establishing baseline performance of new equipment

- Verifying performance before and after maintenance

- Assessing performance of other essential liquid handling equipment such as plate shakers, plate washers, and bulk dispensers

MVS Data Manager Software

Software Features

- 21 CFR Part 11 compliance ready.

- Immediate display of pass/fail, dispense patterns via heat map, and volumetric results for each channel.

- Automatic flagging of all deliveries exceeding tolerance limits.

- Easy exporting of data for analysis or viewing with other programs

- Ability to re-evaluate data visually by modifying the pass/fail criteria after analysis.

- Test the performance of multiple liquid delivery devices using a single plate.

- Ability to use popular conventional microtiter plates when traceability is not a factor.

- Ability to verify and optimize a volume dispensing instrument using specific test solutions such as dimethyl sulfoxide (DMSO).

- Compatible with Microsoft Windows® 7 or Windows® 10.

Artel 800TSNB Plate Reader

The MVS Calibrator Plate is a unique, highly sensitive device used to account for local drift in the daily performance of each MVS Plate Reader. Drift is removed from the MVS calculations by correlating the absorbance measurements from a Plate Reader with those made by the reference spectrophotometer at the Artel Laboratory, which is traceable to national and international standards.

The MVS Data Manager software obtains critical information from the plate bar code concerning the absorbance of each standard as read in the reference spectrophotometer. The Calibrator Plate therefore allows any compatible Plate Reader in the field to generate standardized, traceable results at any location in the world.

The plate is composed of an aluminum frame with alignment apertures and a set of four sealed, custom-manufactured, precision cuvette absorbance standards. These solution-filled standards are manufactured to strict specifications which cover the working absorbance range of the system. This allows for more accurate wavelength-specific corrections of the plate reader for performing MVS calculations. Additionally, temperature dependencies of the QualAssure solutions are accounted for by the Calibrator Plate. A pane of neutral density glass is included to monitor any unlikely change in absorbance of the solution-filled standards.

The plate shaker is interfaced with the MVS Portable Computer to ensure consistent mixing of the QualAssure solutions.

The high-performance, hand-held 2D bar code scanner allows for easy recall of liquid handler devices and ease of use to enter required MVS bar code data into the Data Manager software.

The mobile workstation allows for convenient verification of equipment in multiple locations throughout your facility. The mobile workstation is equipped with two easy-to-clean shelves and an enclosed bottom shelf with locking door to secure supplies.

Verification Plates are black, optical-bottom microplates that significantly improve the overall measurement capabilities of the MVS. When a microplate lot is manufactured, a statistical sampling plan is used to pull plates from throughout the manufacturing run. Proportional dilutions for volumes that span the entire MVS volume range are made on balances calibrated with mass standards traceable to national and international standards. These dilutions are used to characterize deviations from ideal performance within the operating absorbance range of the MVS using the sampling of plates. The statistical sampling plan and test method provide measurements representative of each well in that particular plate lot.

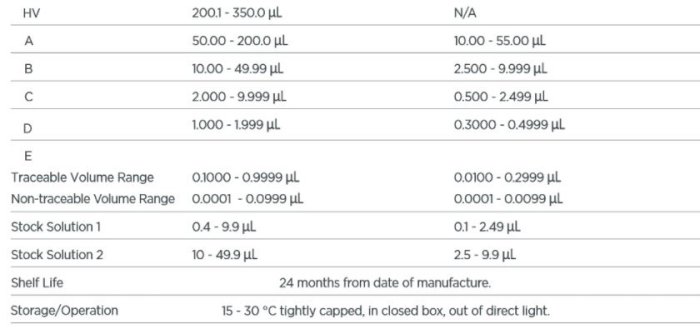

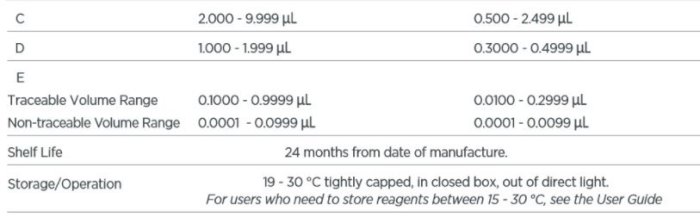

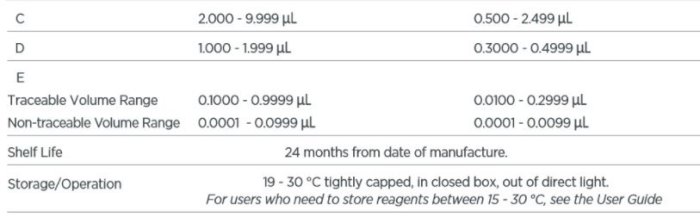

The MVS QualAssure solutions are prepared by Artel and conform to rigorous performance specifications. The solutions contain two dyes: red and blue. As shown in the table below, each of the different QualAssure solutions is employed to cover a designated target volume range. As the volume-of-interest decreases, the appropriate QualAssure solution contains an increased concentration of red dye, thereby maintaining constant signal strength to the plate reader detector. The blue dye is used as an internal standard to measure the solution depth in every well.

The standard MVS QualAssure solutions are aqueous and can measure performance over a wide volume range of 0.0001 to 350 µL.

- 21 CFR Part 11 compliance ready.

- Immediate display of pass/fail, dispense patterns via heat map, and volumetric results for each channel.

- Automatic flagging of all deliveries exceeding tolerance limits.

- Easy exporting of data for analysis or viewing with other programs

- Ability to re-evaluate data visually by modifying the pass/fail criteria after analysis.

- Test the performance of multiple liquid delivery devices using a single plate.

- Ability to use popular conventional microtiter plates when traceability is not a factor.

- Ability to verify and optimize a volume dispensing instrument using specific test solutions such as dimethyl sulfoxide (DMSO).

- Compatible with Microsoft Windows® 7 or Windows® 10.

- x86 Processor: 1.4 GHz or faster

- Memory: 1 GB

- I/O Ports: 3 USB Connectors

- Network: 10/100 Ethernet and 802.11b Wireless

- Storage: 20 GB of hard drive space

- Supported Operating Systems: Windows® 7 or Windows® 10

- Additional Key-span USB adapter (for use with user-specific laptops that do not have an RS232 serial port)

- Cleaning Kit for Calibrator Plate

* Measurement of volumes outside of the traceable volume ranges are not traceable to the national and international standards and no declarations of relative inaccuracy and imprecision are made.

**Stated specifications apply when Artel MVS Plate Readers (ELx800 and 800TSNB) and MVS Verification Plates are used with Aqueous QualAssure and DMSO QualAssure.

Product Installation and Validation

Have your new Artel instruments validated and ready-to-use quickly and efficiently. Certified Artel Application Specialists will set-up, install, and validate your instrument on-site, then train your staff to make best use of it.

- Execution of pre-packaged IQ/OQ protocols to ensure validated instrument performance and operation

- On-site, hands-on training for your laboratory at no additional cost

Installation Qualification (IQ)

Artel IQ protocols ensure proper setup, connection, and communication between all components of the system. Your Artel IQ specialist will perform and provide documentation of the IQ validation procedure, which details the correct installation of the system in your laboratory.

Operational Qualification (OQ)

Artel OQ protocols ensure that the instrument or application performs to its intended specifications in the environment where it will be used. Your Artel IQ specialist will perform and provide documentation of the OQ validation procedure, which details the performance of the instrument or application after a successful IQ protocol is completed.

Technical Services

Artel’s dedicated metrologists, scientists, engineers, and support specialists are here to answer your questions, troubleshoot problems, and help you ensure accurate, precise liquid delivery for reliable assay results.

Tel: 1-888-406-3463, opt 2 (8:00 a.m. to 5:00 p.m. ET)

Email: support@artel.co

Online: Submit online request

Ordering

Please place orders by telephone, fax, email, or mail. Our customer service representatives are available Monday through Friday from 8:00 a.m. to 5:00 p.m. Eastern Time.

Phone: 207-854-0860 | 888-406-3463 toll-free (U.S. and Canada)

Email: orders@artel.co

25 Bradley Drive

Westbrook, ME 04092 USA

International

Fax*: 207-854-0867

*Please include a fax number or email address for confirmation of fax orders.Orders From outside the U.S. and Canada, please see our International Distributor List for contact information.

Free your staff to focus on science and let us provide peace of mind, with Artel warranty and product support programs.

Instrument Warranty Programs

These programs include insurance and shipping within the U.S. and Canada of a loaner instrument.

Standard Warranty

Provides basic coverage against defects in materials or manufacture of the instrument.

Extended Warranty

Provides continued protection against unanticipated expenses associated with instrument repairs.

Product Support Service Programs

MVS Calibrator Plate Recertifications

Provides documented factory recertification and ongoing standardization of measurement results via annual factory recertification of the MVS Calibrator Plate, suitable for Quality Assurance purposes.

On-Site Preventive Maintenance

Provides periodic checks of system components for wear and tear, replacement of worn or outdated parts, and testing for accuracy and precision against factory specifications.

On-Site Installation, Validation, and Training

Provides installation, IQ/OQ documentation, and usage overview for instruments and software. Artel can also revalidate instruments that have been relocated or undergone maintenance or service.

Tel: 1-888-406-3463, opt 2 (8:00 a.m. to 5:00 p.m. ET)

Email: support@artel.co