- Home

- Companies

- Gpi Tanks XL

- Products

- Multiple Tanks On Site

Multiple Tanks On Site

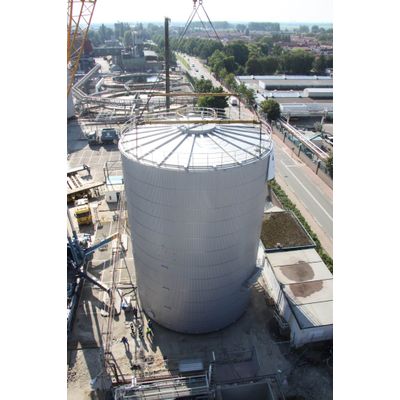

Multiple XL tanks constructed on site, Up to 30 metres high and 30 metres wide, Our efficient process and efficient teams can produce multiple tanks at the same time, When transport is difficult or impossible.

In a multiple tanks on site project, we construct multiple tanks at the same time on site. To do this, we use a central crane for the hoisting work, with different locations around the crane for the various production phases, thereby ensuring a smooth transition between processes.

Moving one large tank from the production hall to its final destination can prove to be an enormous challenge. Transporting a series of tanks is, therefore, even more of a challenge. Although many things are possible, constructing a tank in the production hall and transporting it is not always the most attractive option. If you’re having a series of tanks constructed, a multiple build project may be a sensible decision.

In a multiple build project, we construct multiple tanks at the same time on site. To do this, we use a central crane for the hoisting work, with different locations around the crane for the various production phases. The crane moves the tank being constructed from one phase to the next

- Decoiling

The decoiler unrolls or decoils the stainless steel sheet from the roll, flattens it and cuts it to size. The ends are then welded together, thereby creating part of the hull of the tank.

- Attaching

The parts of the hull of the tank are firstly attached to one another at various points. The actual welding to join the parts together is carried out in a later phase.

- Stretching

The parts of the hull are not entirely the same when they leave the decoiler, so the stretcher ensures that they fit together neatly.

- Welding

The parts are welded together by an automatic plasma welding machine.

- Stretching

The stretcher then makes the welds thinner for a neat finish. This also helps to straighten out any deformation in the welds.

- Grinding, polishing, pickling and passivating

The newest section of the hull undergoes further finishing.

After polishing, the tank is returned to the decoiler for a new plate to be added at the bottom. While one tank is having a layer added, the crane is moving the other tanks for stretching, welding and polishing. By designing the process in this way, we ensure that all machines and manpower are constantly operational, allowing us to use our resources as efficiently as possible during production.

For this to work, your location must satisfy a number of requirements, but we will liaise with you to find the best solution for your project.

Gpi only uses stainless steel for its tanks. Different types of stainless steel are available, and you can choose the type that best suits your industry and uses. In some cases, a combination of materials may be an option, such as a part-duplex material for the lower section of the hull (where the strength requirement is the greatest), and a cheaper stainless steel, such as 304(L) or 316(L) for the upper section. Our experts would be happy to advise. If you’d like to learn more about the materials, please visit our stainless steel page

To guarantee your safety and that of our team, we are VCA and VCA Petrochemicals certified, to name but two. We are also well acquainted with the common and relevant standards and regulations. Learn more about our standards and certifications.