- Home

- Companies

- SR2O Holdings, LLC

- Products

- Scrap Rubber 2 Oil - Municipal Solid ...

Scrap Rubber 2 Oil - Municipal Solid Waste to Renewable Fuels

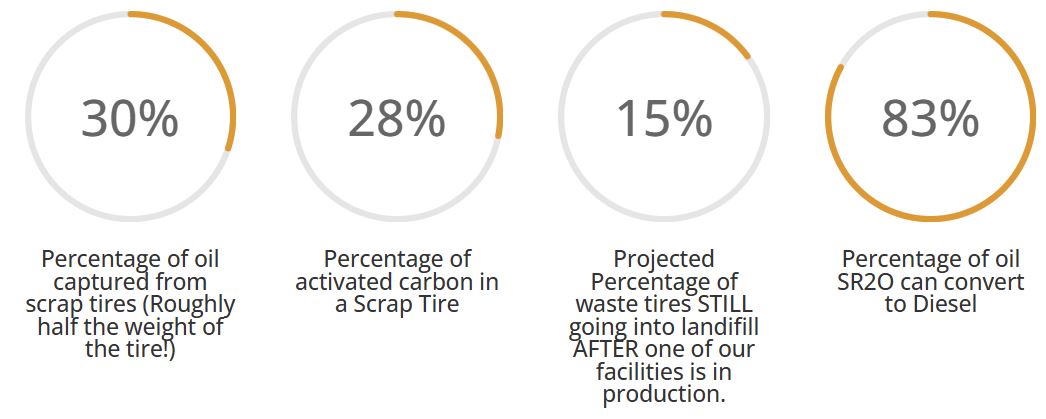

Our Focus on Scrap Rubber Results in High Returns and Drop in Renewable Low Sulfur Diesel Fuel. Scrap Tires Increase Every Year: There is one scrap tire created per person per year in the Unites States of America. This statistic along with dense populations is where our facility is targeted. With the massive amount of scrap rubber already in neglect, and the millions of tires being created each year, we have focused each facility to process over 7.5 million tires per year.

REFINED BY DESIGN

Scrap Rubber 2 Oil uses our 3rd Generation design of our pyrolysis system and our 40 years experience in hydrocarbon refining processes to locate a safe and secure facility to the communities.

LOW EMISSIONS

Our Closed Loop System severely reduces the amount of green house gasses emitted from the recycling of your scrap rubber. Our single line process was permit exempt in the State of Oklahoma when proving scale of the system.

POWER FOR THE FUTURE

Once the system is producing, within 6 hours our facility is generating our own power. Depending upon regional location and local utility and state requirements, the Scrap Rubber 2 Oil Co-generators have the ability to sell electricity back to the grid.

Renewable Fuels for Your Municipality

Scrap Rubber to Oil’s (SR2O) facilities and our technology offer an environmentally friendly method to recycle scrap tires with very attractive economic returns.

Our thermal recovery (pyrolysis) technology is scalable with an initial capacity of approximately 240 tons per day–7.4 million passenger tires per year. Based upon a 90% uptime, a base set of equipment produces the following estimated materials:

Approximately 1.3 gallons of oil per tire to an ASTM 2892 test specification.

This would be equivalent to approximately 8.6 million gallons of oil per year.

Based on feedstock agreements, approximately 8% to 11% of a tire’s weight would be steel. This would create approximately 160 to 220 lbs of high quality steel per ton of feedstock.

An estimated 6.4lbs of commodity grade VersaCarbon™, milled to a 325 mesh, is recovered from a 20 lb passenger tire. This would be equivalent to approximately 21,300 tons of carbon black per year at 90% up-time.

Additional refining and scrubbing of the carbon powder, results in enhanced product quality and improves the profitability for the carbon. Typical Markets that can be serviced with the carbon could be activated carbon for filtration, printer ink and toner, rubberized automotive products, as well as nanotechnology and aerospace fields.

The highly efficient and effective SR2O process allows the generation of electricity that exceeds the plant requirements. This is in addition to the non-condensable gases generated in the process that is used as fuel to maintain the operation of the pyrolysis units. This reduces the overall utility costs for the ongoing operations of the facility.

A typical site layout includes several focused business practices.

Feedstock Receiving/Unloading:

Our feedstock receiving and processing area is optimized for independent businesses gathering used scrap tires and rubber to unload within minutes and return back to the road.

Feedstock Storage:

We firmly believe our unique and fireproof storage solutions for chipped rubber feedstock is the safest storage in the nation. The storage system holds up to 2 months supply of feedstock and has the ability to feed close to 400 tons per day of our feedstock to our proprietary and proven thermal recovery units.

Scrap Rubber Conversion:

Our Scrap Rubber Division evaluates the use of our three (3) types of thermal conversion systems that have been in the recovery markets for years. Depending upon the market area and types of scrap tires, scrap rubber, green rubber and other types collected will determine which of our time proven practices will be employed into the system. Different temperatures, time and process types will vary the final production of liquid hydrocarbons at each site location.

Commodity Product Production Areas:

Condensable gases are cleaned and converted to green, renewable liquid hydrocarbons that are sold to market buyers. Recovered Steel is recycled, and recovered carbon black (rCB) is cleaned and refined to meet or exceed the proposed ASTM (D8178) standard.