NEFCO - Dual Surface Baffle System

The Dual Surface Baffle has a wedge-shaped configuration with identical upper and lower surfaces. The upper surface is identical to the Stamford Baffle 3.0® design, using the 30° inclination angle and the same algorithm to determine the baffle’s horizontal projection based on clarifier diameter. The lower surface is a mirror image of the upper and is inclined back to the clarifier wall. The configuration of the baffle allows the lower portion to be retrofitted to any existing NEFCO Stamford Baffle, upgrading it to the Dual Surface configuration.

The Dual Surface Baffle has a wedge-shaped configuration with identical upper and lower surfaces. The upper surface is identical to the Stamford Baffle 2.0® design, using the 30° inclination angle and the same algorithm to determine the baffle’s horizontal projection based on clarifier diameter. The lower surface is a mirror image of the upper and is inclined back to the clarifier wall. The configuration of the baffle allows the lower portion to be retrofitted to any existing NEFCO Stamford Baffle, upgrading it to the Dual Surface configuration.

Innovations

An advanced Density Current Baffle specifically designed for high flow situations.

Solutions

The Dual Surface Baffle continues to reduce TSS as flow increases.

Revolutionary

The wedge shape is build on the SB2.0 technology to achieve even more.

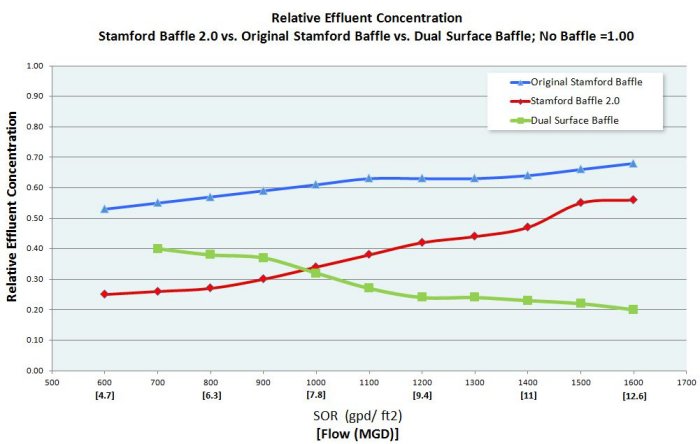

NEFCO’s Dual Surface Density Current Baffle was developed through the company’s CFD Baffle Study. This baffle is designed for larger clarifiers operating at very high flow and has the potential to reduce effluent solids by as much as 80%. As a part of its CFD Baffle Design Study, NEFCO engineers began to explore alternative baffle configurations that might further improve baffle performance. These new configurations were inspired by the predicted flow patterns of the density currents around the baffle.

The study showed that:

- The Dual Surface Baffle has the potential to reduce clarifier effluent solids to a far greater extent than the Stamford Density Current Baffle.

- The performance of this baffle improves as a function of clarifier size.

- The performance of this baffle improves with the increased effluent flow.

The Dual Surface Baffle has a wedge-shaped configuration with identical upper and lower surfaces. The upper surface is identical to the Stamford Baffle 2.0® design, using the 30° inclination angle and the same algorithm to determine the baffle’s horizontal projection based on clarifier diameter. The lower surface is a mirror image of the upper and is inclined back to the clarifier wall. The configuration of the baffle allows the lower portion to be retrofitted to any existing NEFCO Stamford Baffle, upgrading it to the Dual Surface configuration.

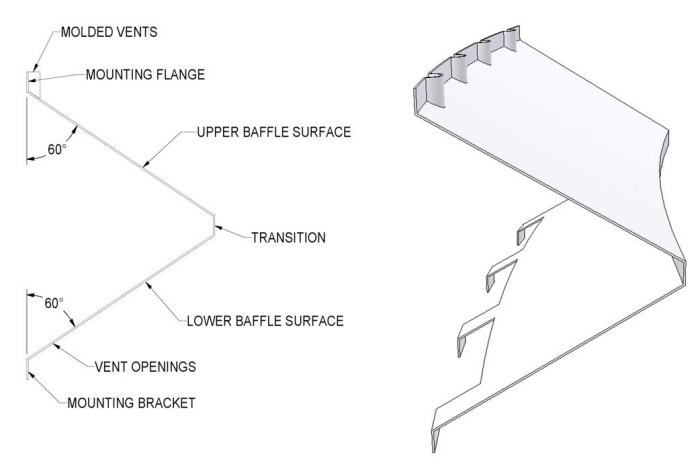

The basic design of the Dual Surface Baffle is shown in the graph to the right. The baffle is wedge-shaped, with identical upper and lower surfaces that fasten to the tank wall. The inclination angle and horizontal projection of the Dual Surface Baffle are identical to those of the Stamford Baffle 2.0®. The upper surface of the baffle includes the integrally molded vents of Stamford Baffle 2.0®.

The Dual Surface Baffle is comprised of individual upper and lower baffle sections or “modules.” Each module combines the baffle panel, the baffle bracket (upper panel only), the vents and the mounting and stiffening flanges in a one-piece molded fiberglass unit eight feet long. The vents in the upper section are the standard, integrally molded vents found in Stamford Baffle 2.0®. The lower section features large rectangular openings formed as a part of the baffle mounting flanges. These openings serve to inhibit solids from collecting inside the baffle and provide a convenient means of cleaning the baffle periodically, if necessary.

The Dual Surface Baffle modules are attached to the tank wall with stainless steel anchors. This baffle is not intended for use in clarifiers with inboard launders. Mounting holes are factory drilled and sealed. Adjacent modules fasten together at a molded recess that forms a ship-lapped joint. Sections of the baffle may be cut as required to fit around piping and other obstructions. The baffle’s laminate features a tough, corrosion-resistant and uv-suppressed fiberglass resin specifically formulated for use in industrial and municipal waste treatment applications.