- Home

- Companies

- Microrite Cleanroom Solutions

- Products

- Microrite - Neutrally Buoyant Tracer ...

Microrite - Neutrally Buoyant Tracer Particle

Tracer Particles should remain visible from where they are diffused into the clean air system being tested all the way to the air return. This allows for the visualization of air flow directions and air mixing in both unidirectional and non-unidirectional air flow cleanrooms. Microrite Tracer Particles have an extremely low vapor pressure, creating Tracer Particles that take up to 20 minutes to evaporate leaving no residual Tracer Particles on HEPA filters.

More importantly it allows for visualization of Combination-Flow cleanrooms and the interface between unidirectional and non-unidirectional air flows. This is extremely important in aseptic manufacturing where visualizing air flow in conjunction with operator movement at the interface between Grade A and Grade B is critical to the evaluation, qualification and regulatory review of aseptic operations.

The Tracer Particles used by Microrite, Inc. are NOT SMOKE PARTICLES. When properly diffused, a Neutrally Buoyant cloud-like fog of Tracer Particles sized between 0.2mM and <1.0mM is released into the cleanroom environment. These sterile particles are comprised of USP Grade Materials Such as Triethylene Glycol, Monopropylene Glycol, Dipropylene Glycol and purified water. The cloud of Tracer Particles is Oil and Glycerin Free, non-condensing, FDA GRAS approved and is non-toxic. For typical Air Flow Visualization Studies, this fog does not condense and pool up on cleanroom surfaces or cleanroom equipment.

The Tracer Particle Solution is vaporized at ~320°C creating a sterile and hot vapor that exits from the Cleanroom Vaporizer into an expansion chamber, mixing with inlet air and traveling via a high temperature silicone tube to the Diffuser System. The Diffuser System/manifold releases a cloud of very small Tracer Particles that cool when exiting the diffuser becoming Neutrally Buoyant when entering the air stream. Neutrally Buoyant Tracer Particles are not affected by gravity and will accurately follow the air currents and identify turbulence, dead spaces and eddy currents.

For cleanroom applications, particles which are Neutrally Buoyant are influenced only by air currents within the cleanroom or area being tested. Gravity and the particle cloud temperature and pressure do not influence their behavior during the testing.

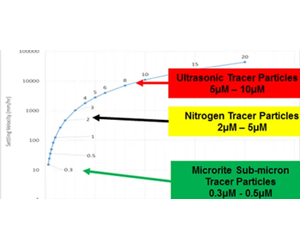

Microrite’s Tracer Particles have a Very Low Settling Velocity compared with Water CO2 or Nitrogen Based “Cleanroom Foggers”

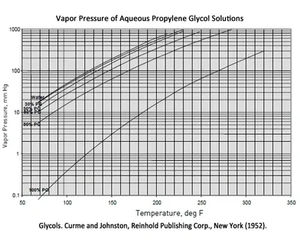

Vapor Pressure

Water, CO2 or Nitrogen Based ”Cleanroom Foggers” produce a high vapor pressure particle cloud that evaporates rapidly under normal atmospheric conditions and condenses rapidly once the cloud reaches its saturation vapor pressure.

References

Why are other Cleanroom Foggers Unsuitable for Testing Medical Product Cleanrooms?

Per CETA Certification Guide for Sterile Compounding Facilities CAG-003-2006 -13 Revised May 20, 2015 Section 13.5:

- Water based fog generators such as CO2 and liquid nitrogen create a fog that is heavier than air and do not always provide for an accurate representation of the actual air patterns.

- The smoke source should be as close to neutrally buoyant as possible. For example, when generating the fog in an area with no detectable airflow, it should not “fall out” or “drop”.

- Fog streams that are heavier than air may not detect updrafts and turbulence that are detected with a generally neutral buoyant detection stream.

The Controlled Environment Testing Association (CETA) is specifically referenced in USP 797 Section 5: Certification and Re-certification:

Before a compounding area is used to compound either Category 1 or 2 CSPs, it must be certified using procedures in the current Controlled Environment Testing Association (CETA) Certification Guide for Sterile Compounding Facilities or an equivalent guideline.