- Home

- Companies

- Next Generation Recycling Maschinen ...

- Products

- NGR - Model C:GRAN - ...

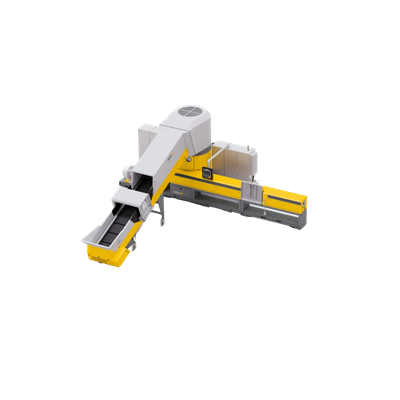

NGR - Model C:GRAN -Cutter-Compacter-Extruder Combination System

If the material has a high moisture content, the plastic recycling system C:GRAN is the ideal solution. Flakes or films with a residual moisture up to 12 % are processed in this plastic recycling system without problems thanks to its excellent pre-drying properties.

GRAN is distinguished by its enlarged cutter bin with advanced cutting geometry. The combination of a fast-moving rotor blade with efficiently arranged guides ensures a continuous energy input into the material. This ensures that the material is optimally prepared for the subsequent extrusion process. The C:GRAN is also an ideal option for a component of a cascade extruder or a compounding system.

Depending on the application, this machine can be equipped with a wide range of melt filters, such as continuous filters, and-melt-filter, piston filters, backflush filters, etc.

- Preparation of flakes and films with residual moisture up to 12 %

- Output rate up to 3,000 kg/h (6,610 lbs/h) depending on type

- Maximum automation thanks to AUTO-Pilot

- Ideal as a component of a cascade or compounding system

- Compatible with a wide range of melt filters

The operating principle of C:GRAN

The shredding, homogenization and drying/heating of the plastic waste takes place in the cutter bin by rotating blades. Specially arranged feeders ensure additional compaction of the material. The cut and dried material is conveyed into the extruder screw by centrifugal force and feeders.

The automatic intake slider ensures constant extrusion conditions. The advanced extruder screw technology allows gentle melting even at high throughput rates.

Processing of wet materials

Due to the heating of the plastic in the cutter bin, materials with residual moisture (e.g. from washing plants) can also be processed. The material is dried in the cutter bin. At higher residual moisture levels (>5%), Dry-Boost provides additional drying performance.

Optimized material processing

Thanks to the optimal new cutter design and efficiently arranged material guides, the material is well cut, compressed and heated. The high level of processing in the shortest possible time optimally fills the screw and thus provides high output rates with low energy consumption.

Auto-Pilot

Automated from start to finish, the NGR Auto-Pilot controls the feed, the energy input in the cutter-compactor and the extruder load completely autonomously. The sophisticated software intervenes in the process even in the event of minimal quality fluctuations in order to stabilise it without manual operator intervention.

Efficient extruder

Due to the high degree of material preparation and the optimized screw design for every material ensures best possible homogenization and highest output with low energy demand.

Extruder screw

Specially developed for the challenges of recycling, the extruder screws provide optimum melt homogeneity. The extruder screw, which was designed specifically for use with the cutter compactor, takes the already heated material and provides high output rates.

Control unit

All equipment functions from feeding to pelletizing are controlled automatically from the easy-to-read NGR touchscreen. Recipes are managed in the operator control unit, which increases traceability, provides ease of use, and ensures equipment parameters are set properly.

Pellet size

In addition to high quality, the uniform pellet size also provides for homogeneous mixture in new material. NGR thus plays an indirect role in ensuring consistent quality in the final product.