- Home

- Companies

- Next Generation Recycling Maschinen ...

- Products

- NGR - Model P:REACT LSP - Lquid State ...

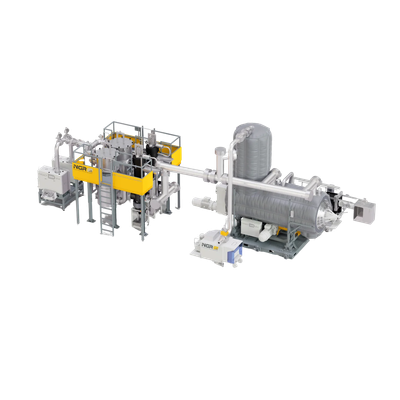

NGR - Model P:REACT LSP -Lquid State Polycondensation Machine

The PET recycling machine P:REACT makes it possible to revolutionize the PET recycling process. It transforms PET waste and PET bottle flakes into food-grade recycled PET in minutes.

Thanks to the advanced LSP (Liquid State Polycondensation) process, the PET melt phase is used to trigger the polycondensation of PET. The reaction speed in the PET melt is significantly higher than in the solid phase. The clear advantage: IV values, controlled with pinpoint accuracy, that can be even higher than those of the original starting material – depending entirely on your objectives.

Additionally, we have paid attention to highest energy efficiency and minimization of operating costs when developing the PET recycling machine P:REACT – profitability is thus guaranteed.

- PET recycling at the highest level

- Output rate up to 3.000 kg/h (6,600 lbs/h) depending on type

- Continuous process with enormous process stability

- Significantly higher energy efficiency than conventional SSP applications

- Approval by FDA and EFSA for 100 % food safety

The LSP-Process utilizes the inherent capability of PET to condensate in the molten phase under vacuum. This condensation leads to an increase of IV. The high performance vacuum effectively decontaminates the material from harmful chemicals, – securing further use of the material for 100% food contact.

As molten PET enters the vertical part of P:REACT, strands are formed to create a suitable surface to volume ratio. The material is then collected in a horizontal drum and slowly pushed forward. Condensation starts immediately as the strands are formed and is set forth until PET exits P:REACT. IV increase is controlled by the residue time and the vacuum level of the molten PET inside P:REACT and therefore can be adjusted to a desired level. The settings of parameters allow the control unit to maintain the desired IV-level within a small tolerance-band.

The decontamination performance is extremely effective, as carried out in the liquid phase of PET. The cleaning of the material exceeds limits set by recognized food safety standards, but also effectively removes spin oil from fibers.

The continuous operation of P:REACT provides rPellets within a narrow IV-range, suitable for usage in valuable high end applications (i.e. fiber-spinning or sheet extrusion). Batch related IV-fluctuations are simply designed out.

The favorable conditions inside P:REACT (temperature/ surface:volume ratio of the melt/high performance vacuum), easily initiates the condensation-process of PET. This results in IV increase rates of some 0.01 dl/g per minute. Faster reaction leads to faster results and a more profitable operation.

P:REACT actively controls the residue-time of the PET-melt and the vacuum inside the reactor and automatically adjusts the machine parameters to receive the desired IV at a consistent level.

The separation of harmful contaminants, as spin-oils or those components not desired for food contact, are removed by high performance vacuum. This high decontamination performance allows the use of P:REACT for many applications for highest flexibility.

The European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA) both confirm that the Liquid State Polycondensation (LSP) process is fully food-safe.

The recycling of PET requires the material to be melted. P:REACT uses the melt-energy for condensing PET. The reactor itself only maintains the heat-level. P:REACT is therefore highly energy-efficient, which results in low operating costs.