- Home

- Companies

- Next Generation Recycling Maschinen ...

- Products

- NGR - Model X:GRAN - ...

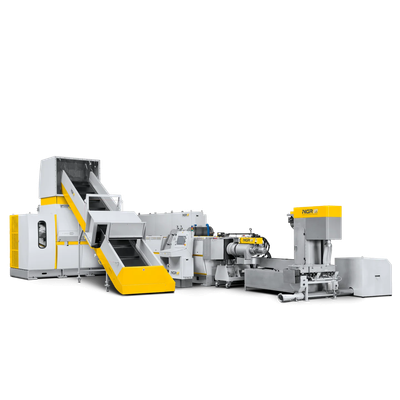

NGR - Model X:GRAN -Shredder-Feeder-Extruder Combination System

X:GRAN is setting new standards in the high-output segment while at the same time working at maximum efficiency and with improved production capability.

Robust and extremely capable – the power of the inhouse plastic recycling machine X:GRAN is clear to see. The X:GRAN solution does more than just process all types of plastics waste. It even handles bulky materials such as large bales and carpet pads – without any additional preliminary size reduction.

X:GRAN is also at the cutting edge of efficiency. Thanks to its material-conserving shredders and optimally guided extrusion, you can be sure that the X:GRAN will achieve sustainable zero-waste production (all production waste fed back in).

- Easy, material-conserving processing, even for difficult industrial plastic waste

- Output rate up to 2,500 kg/h (5,070 lbs/h) depending on type

- Switching on and off by a single button

- Quick and easy start-up and shut-down at any time

- Small footprint saves space

Plastic waste is processed by a heavy duty shredder operating at low speed for gentle size reduction and minimal loss of material properties. In this process, a hydraulic ram pushes the material to be shredded onto the shredder shaft.

The shredder and extruder drives are controlled separately and automatically, based on load.

After shredding, the ground up material is fed directly into the extruder via the feeder screw. In the extruder, the material is brought to a uniform melt temperature and degassed, if necessary.

All the components are positioned in close proximity to prevent oxidation of the material and to make optimal use of heat from the shredding process.

In a single process step, the slow-turning shredder blades grind up the plastic waste and the shredded material is then fed continuously to the extruder by the feeder screw.

Large, thick or bulky waste can be processed without pre-shredding as long as pieces fit into the hopper opening.

The control system provides for smooth start-up of equipment components. Restart after unplanned shutdown in less than two minutes with full hopper and full extruder.

The material level in the hopper is constantly measured and the feed is regulated accordingly. Discontinuous filling of the conveyor is possible – the NGR control unit does the rest.