- Home

- Companies

- Yate Magnetics Co.,Ltd.

- Products

- Ningbo-Yate - Magnetic Grate Separators

Ningbo-Yate - Magnetic Grate Separators

Grate Magnet Separators are designed to separate contaminants in free flowing materials such as carbon black, drugs, chemicals, cosmetics, plastics, food industries and so on. These units are easily installed in any hopper or floor opening, chute or duct. It makes product stream free flowing products to come in directly contact with the grate magnets.

Construction:

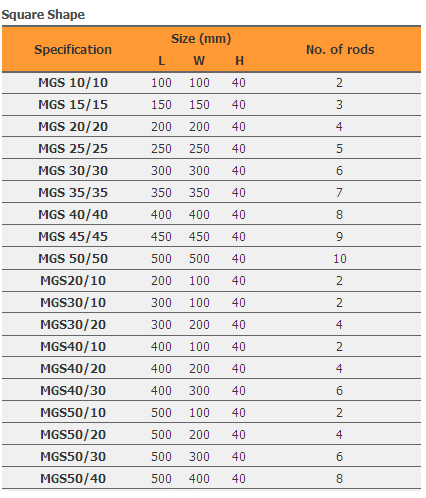

YT magnetic grate are constructed by a row of magnetic bars which are fixed by frames in various shape. These magnetic grates can be square, rectangle, round, oval, triangle, rhombus or irregular polygon, to suit for different position. Center distance of bars is usually 2 inches. All the frames and shells are 100% stainless steel.

When anything containing iron substances passes through the framework, Iron particles are attracted to the bar magnets by magnetic fields, by using grate separators, your equipment and facilities will be protected, while your products will be safe for consumption.

Construction:

YT magnetic grate are constructed by a row of magnetic bars which are fixed by frames in various shape. These magnetic grates can be square, rectangle, round, oval, triangle, rhombus or irregular polygon, to suit for different position. Center distance of bars is usually 2 inches. All the frames and shells are 100% stainless steel.

When anything containing iron substances passes through the framework, Iron particles are attracted to the bar magnets by magnetic fields, by using grate separators, your equipment and facilities will be protected, while your products will be safe for consumption.

Special designs for some magnetic grate application:

The baffle is used to direct the materials onto or close the rods when they flow down. By this way, more contaminants will be attracted. Baffle can be small rods or 90 degree angle.

Adding handles aims for easy operation. Especially with big size which is too heavy to handle. Another advantage of this design is to avoid contaminants dropping down when holding.

Multiple layers design

The one in the picture is double layers. Of course, more layers, much purer the product is. However, it depends on the condition of products.

Easy-clean design

This design is more expediently to be cleaned. Just take out the magnetic core , the iron impurities will fall from the shell.

- Finishing: Well polishing and welding to meet food grade.

- Material of shell: SS304, SS316 and SS316L seamless steel tube

- Working Temperature: Standard working temperature is?80?, but if high temperature is required, we can offer up to 350? to meet your special applications

- Various designs available. Standard type, Easy clean type, one layer, multilayer

- Also takes customers’ designs.

- Customer designs, specifications can be fulfilled.