- Home

- Companies

- Zeltex LLC

- Products

- Zeltex EvoNIR - Model 4.0 - NIR ...

Zeltex EvoNIR - Model 4.0 -NIR Evolution On-Board Analyzer

EvoNIR 4.0 Analyzer with ISOBUS protocol can be connected to any virtual terminal with built-in ISOBUS task controller and can be installed on forage harvesters, combines, balers, forage wagons, slurry tankers, compactors, feed mixers and portable in a carrying case.

EVONIR is the most versatile NIR analyzer on the market, designed for precision agriculture. It can be mounted on forage harvesters, combines, balers, forage wagons, slurry tankers, compactors, feed mixers, or used as a portable device (AGRINIR). This advanced sensor measures dry matter, protein, starch, fiber, neutral detergent fiber, acid detergent fiber, ash, sugar, and more in real-time with outstanding accuracy.

- Real-Time Analysis

- Track All Data from the Field

- Improve Future Treatments Efficiency

EVONIR enables traceability from field to farm, supporting crop growth, fertilization, biogas production, and dairy farming. Farmers, growers, and contractors achieve unmatched precision with real-time insights.

EVONIR delivers precise, real-time data to ensure high-quality silage and traceability during harvest.

- Eliminates guesswork to get consistent feed quality

- Real-time grain and forage analysis to create prescription maps

- Optimize inputs and maximize field performance with accurate, data-driven insights.

Harvest more value

EVONIR analyzer enables the precise application of slurry based on pre-determined crop nutrient requirements and regulatory standards.

EVONIR can be installed on trailed, self propelled and drag-hose to measure N, P, K levels accurately. This ensures efficient nutrient management and compliance with agricultural guidelines, enhancing productivity.

EVONIR is DLG certified for cow, pig, mixed slurry and digestate.

Nutrient optimization, cost efficiency

EVONIR on self propelled mixers measures dry matter and key nutrients in real time, ensuring precise and consistent ration preparation. The system automatically recalculates the weight to be loaded for each component, optimizing feed accuracy. On trailed mixers, EVONIR delivers valuable data on TMR quality and homogeneity, supporting improved livestock nutrition and performance.

Manage forage variability

ISOBUS built-in

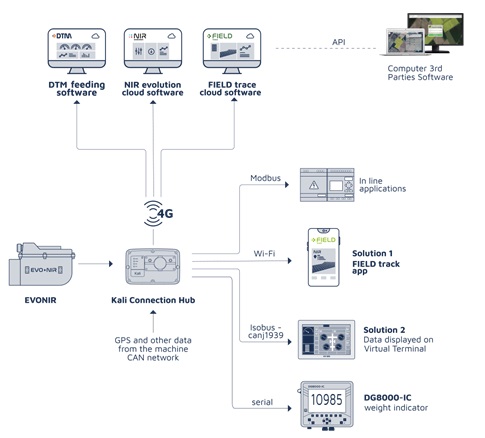

EVONIR, utilizing ISOBUS or CAN J1939 protocols, seamlessly communicates and displays real-time NIR data on machinery virtual terminals. This integration significantly improves operational efficiency, enabling precise and informed decision-making in the field.

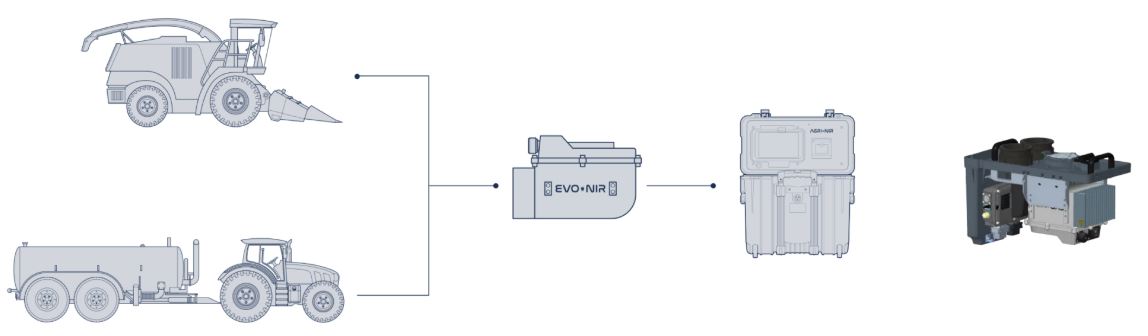

The EVONIR sensor offers exceptional versatility, allowing it to be easily transferred between different agricultural machines. Its cross-compatibility boosts operational efficiency, reduces costs, and delivers top performance in a wide range of farming activities, like harvesting or spreading. EVONIR is an indispensable tool for modern precision agriculture, empowering farmers to enhance productivity.

EVONIR can be installed in-line in production plants for continuous, real-time monitoring of product quality. This advanced NIR analyzer ensures accurate analysis of key parameters, optimizing production efficiency and can be installed in various types of production lines like alfalfa drier plant, cereal elevator, sugar cane plant and olive mill.

The way farmers, growers and contractors run their operations is changing . The installation of NIR sensors on OEM agricultural machines represents a significant leap forward in enhancing agricultural efficiency. From precise crop monitoring to optimal harvesting conditions, quality control, and data-driven decision making, NIR sensors unlock a realm of possibilities for farmers.

Forage harvester

Quick and accurate measure right in the field.

Combine

Small improvements in grain harvesting bring large increases in profits.

Forage wagon

Combine NIR data and weight data to create heat maps.

Baler

Moisture and nutrient value for each bale.

Compactor

Know relevant information regarding each and every bale (nutrients, weight).

Slurry tanker

Real time N,P,K analysis and variable rate application.

Trailed mixer

Homogeneity and TMR analysis.

Self propelled mixer

Real time analysis and adjustment for each component.

AGRINIR 4.0

Portable NIR analyzer.

In Line

EVONIR can be installed into production line to optimize the process.

- Harvest optimization: helps determine the best time for harvesting, improving crop quality and yield.

- Quality control: measures key parameters such as moisture, protein, fat and fiber content, ensuring that forage and other agricultural products meet desired standards.

- Operational efficiency: reduces the need for manual sampling and laboratory analysis, speeding up operational processes and reducing downtime.

- Waste Reduction: provides accurate data that allows machinery to be adjusted to minimize losses and waste during harvesting and processing.

- Resource management: improves fertilizer and additive management, enabling more precise application and reducing environmental impact.

- Traceability and documentation: facilitates batch traceability and documentation of quality parameters, useful for certification and regulatory compliance.

- Data-driven decisions: provides detailed information that helps farmers make more informed decisions about field and resource management.

- Adaptability: can be integrated with other agricultural management systems, creating a comprehensive and interconnected monitoring network.

EVONIR features a built-in predictive engine based on machine learning technology that increases the accuracy of real-time predictions. These new improvements aim to simplify customers’ lives by reducing manual operations through automatic transfer of data and spectra, as well as automatic updating of firmware and calibration curves.

NIReverse is the one-stop solution to exploit the potential of NIR analyzers all year-round. When the harvesting-spreading season ends, harness the power of your NIR sensor for monitoring feed quality on-the go. Take off the sensor from the machine, put it on the trolley case and gain outstanding feed management with superior flexibility. Dinamica Generale introduced the concept of Reverse Engineering to the NIR sensor applied on agricultural machines.

- Sensor: Sensor InGaAs, 256 pixels, with Peltier cooling

- Spectral Range: 950-1800 nm

- Optical Resolution: FHWM 6nm

- Type of measurements: Diffuse Reflectance

- Grade Protection: IP69K

- Communication: WiFi, 4G, Isobus,CanJ1939, Mondbus

- Software: Field Trace, DTM, NIR Evolution

- Dimension: 17 x 23 x 17h cm - 4 kg

- Material: Anodised Allumiun - Military standard

- Working Temperature: -10 / +50 °C (14 / +122 °F)

- Power: 12-32 v