NNZ - Container Liners for Industrial Packaging

Container liners offer food-grade protection for transporting food commodities. Using container liners you transform standard intermodal ocean containers into dry, contaminant-free bulk transportation systems for food.

Typical content packed in: Container liners

- Dry beans and pulses

- Grain

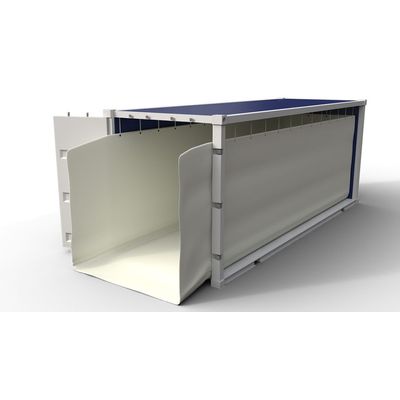

Partial container liners

The liners offer added protection for shipping products in intermodal shipping containers. The liners are fabricated with durable coated woven PE fabric, with full-body welded seams ensure your products arrive contaminant-free. The liner walls are suspended by cable ties attached to roof lashing rings along the length of the container. The liners are lightweight and flexible for easy handling and installation. Installation requires the use of a bulkhead, which provides the fourth wall.

Full container liners

The liners are fabricated with durable coated woven PE fabric, with full-body no leak welded seams to ensure products arrive contaminant-free. The built-in bulkhead acts as a fourth wall at the door end of the container to hold the product in place. Installation requires four steel bracing bars.