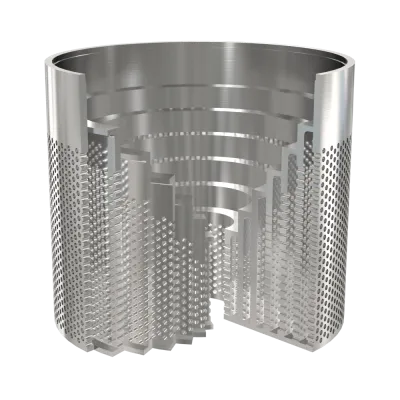

MASCOT - Model MegaFlo -Noise Attenuation Trim for Control Valves

The MegaFlo Noise Attenuation Trim by MASCOT Valves is designed to effectively minimize gaseous noise in control valves, making it crucial for industries where sound reduction is imperative, such as chemical plants, refineries, and power plants. Engineered after extensive research, the MegaFlo trim is versatile, being applicable across various stages - from one to seven - to reduce noise levels by up to 30 dBa. The trim incorporates several engineering principles, including controlled velocity during pressure reduction, expanding galleries, and frequency shift technology, to achieve optimal noise reduction. The sound barrier design further enhances its efficiency. Additionally, the MegaFlo trim is designed for easy retrofit into existing GFlo and DeFlo SCV models, eliminating the need for extra components. Its construction utilizes a variety of materials like SS 316, Monel, and Hastelloy, catering to different industrial demands.

The MASCOT MegaFlo trim effectively reduces the gaseous noise in control valves. MegaFlo design is a result of extensive research and engineering study. Various principles have been incorporated into the trim design allowing it to be used in varied applications like chemical plants, refineries, power plants, process industries, nuclear industries and wherever a highly effective noise reduction valve is required.

The MegaFlo trim can be applied with 1 to 7 stages effectively reducing the noise by up to 30 dBa.