Nova Pellet Arco International Srl

- Home

- Companies

- Nova Pellet Arco International Srl

- Products

- Nova - Model N-Midi - Pelletizing ...

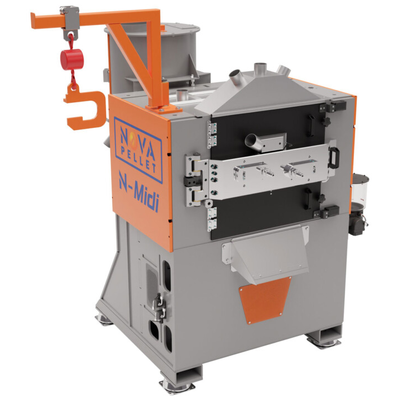

Nova - Model N-Midi -Pelletizing Pellet Mill Systems

Nova Pellet, through its complete pelletizing systems with the N-MIDI Pellet mill, offers its clients a cost-effective solution for pellet production, thanks to the low ratio between installed electrical kW and hourly pellet production. The N-MIDI plants are ideal for continuous pellet production in large carpentries and sawmills or for creating an automated pellet production factory. Nova Pellet can adapt its technological solutions to meet the specific needs of its clients.

Most popular related searches

pellet mill

pelletizer

pelletizing

pelletizing system

pelleting system

pellet plant

screw feeder

automatic pelletizing

level sensor

screw conveyor

The N-MIDI pellet mill by NovaPellet is designed to optimize pellet production costs, thanks to superior energy efficiency. This innovative machine offers a low ratio between installed electrical kW and hourly pellet production, allowing for significant economic savings.

Medium quantity production, ideal for inline systems.

- ? die:420 mm

- ? press rollers:206 mm

- Dimensions:1900x1400x2200 mm

- Weight:4500 Kg

The N-MIDI represents a new generation of pellet mills, developed with advanced technologies that surpass traditional feed industry standards. These improvements result in:

- Energy savings thanks to high-efficiency motors.

- Reduction of maintenance costs and downtime.

- High-quality pellet production, suitable for both domestic and industrial markets, without the use of additives or binders, ensuring a natural and safe product.

- Morphology: Sawdust or material with granulometry between 0.5 mm and 3 mm.

- Moisture content: Between 8% and 14% maximum.

- Characteristics: Suitable for all types of wood or other materials, as long as they are free from iron.

- Monoblock structure with feeding system based on the patented N-PLUS pellet mill technology.

- External press roller adjustment, modifiable during the working cycle without interruptions.

- No use of additives or binders, even natural ones.

- Optional inverter for managing the main motor.

- Centralized loading of sawdust into the compression die via a single screw conveyor.

- Easy-to-replace ring die with reduced tool consumption.

- Automatic lubrication with vegetable oil at the beginning and end of the cycle to prevent material hardening in the compression circuit.

- Water and air mixer for humidifying the raw material using vaporized water.

- Compact design with reduced machine footprint, minimizing cleaning and maintenance times thanks to direct access to the pelletizing area.

- High-resistance belt transmission: Equipped with toothed belts ensuring durability, reliability, and maximum efficiency in motor power transmission.

- Completely Made in Italy: Ensuring the highest quality and reliability.

- Mechanical and electrical operation system controlled via Siemens PLC and Touch Screen interface.

- Manual press roller adjustment, allowing precise positioning on the compression die.

- Automatic loading system via a mixer tank and a screw feeder, managed by an inverter in proportion to the torque of the die.

- Front pellet evacuation.

- Customizable compression die holes from 14 to 57 mm, depending on the material being pelletized.

- Mechanical level sensor in the loading tank.

- Automatic lubrication with grease for press rollers and spindle, with manual motor greasing.

- Advanced safety features, including electro-locks on access doors and protective covers for motor belts.

- Integrated lifting hooks for forklifts and preparation for dust and steam extraction connections.

- User and maintenance manual included, with CE marking.