- Home

- Companies

- Nova Pellet Arco International Srl

- Products

- Nova - Model N-Plus - Pellet Plant

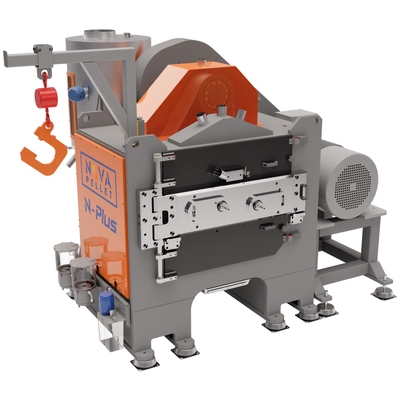

Nova - Model N-Plus -Pellet Plant

The pellet plant with the N-PLUS Pellet mill are complete systems for continuous and automatic pellet production, designed for large-scale production quantities and high-quality final pellets. With N-PLUS systems, you can offer the market a top-tier product, suitable for all major quality certifications, and become a leading player in the sector. N-PLUS plant, based on Nova Pellet's twenty years of experience, allow for low-cost pellet production in terms of energy consumption, required personnel, and maintenance costs. Production capacities are adaptable to customer demands and can be increased in successive stages.

The N-PLUS pellet mill represents technological excellence in pellet production, offering significant economic savings through a design that optimizes the ratio between installed electrical kW and hourly production. Developed with cutting-edge technologies and patented innovations, the N-PLUS reduces operational and maintenance costs, while ensuring the production of the highest quality pellets.

The pellet produced is completely free of additives or binders, making it ideal for both domestic and industrial markets.

- 610 mm

- 277 mm

- 2500x2700x2500 mm

- 11000 Kg

Input Material Characteristics

- Morphology: Sawdust or materials with granulometry between 0.5 mm and 3 mm.

- Moisture content: Between 8% and 14%.

- Characteristics: Compatible with all types of wood or materials free from ferrous components.

Technological Innovations

- Exclusive Patents:

- “Pellet Production Machine Frame”: Innovative design ensuring robustness and stability.

- “Pellet Production Feeding System”: Optimizes machine efficiency, reducing energy consumption.

- Press roller adjustment: Externally adjustable, allows changes during the production cycle without interrupting work.

- Additive-free production: Ensures pure pellets, without the use of natural or synthetic binders.

- High-efficiency motors: Ensure optimal energy savings, reducing operating costs.

- Inverter for main motor (optional): Allows advanced control and optimized motor management.

- Centralized feeding system: Sawdust is fed into the die via a central screw conveyor, ensuring a uniform and steady flow.

- Robust press rollers: Fixed to the pellet mill structure for enhanced stability and durability.

- Ring die: Easy to replace with reduced tool consumption, improving production efficiency.

- Vegetable oil additive: Prevents the hardening of material residues in the compression circuit during machine downtime.

- Water and air mixer: Humidifies the raw material with vaporized water, improving pellet quality.

- Compact design: Designed to minimize footprint and facilitate integration in various production environments.

- Simplified maintenance: Pelletizing area opens easily for rapid cleaning and tool replacement.

- High-resistance belt transmission: Equipped with toothed belts ensuring durability, reliability, and maximum efficiency in motor power transmission.

- Automatic lubrication: Grease lubrication system for press rollers and spindle, reducing manual interventions and extending machine life.

- Advanced control system: Managed via Siemens PLC with Touch Screen, offering simple and precise supervision.

- Remote connection: Electrical panel equipped with Ethernet modem for remote management.

- Manual press roller adjustment: Ensures optimal positioning on the compression die, adaptable based on production needs.

- Loading system: Equipped with a mixer tank and screw feeder, regulated by an inverter, proportional to the die’s operating torque.

- Rear pellet evacuation: Designed for efficient pellet discharge.

- Customizable die: Compression hole length varies from 12 to 75 mm, adaptable to different pelletizing materials.

- Mechanical level sensor: Installed on the loading tank for constant material monitoring.

- Advanced safety: Electro-locks on access doors and protective covers for motor belts.

- Ease of handling: Integrated lifting hooks for forklifts, simplifying relocation and installation.

- Dust and steam extraction preparation: Easily integrates with extraction systems, improving the working environment.

- Certifications and Manual: The N-PLUS complies with CE regulations and comes with a detailed user and maintenance manual.