- Home

- Companies

- Jiangyin Nuoheng Metal Products Co.,Ltd

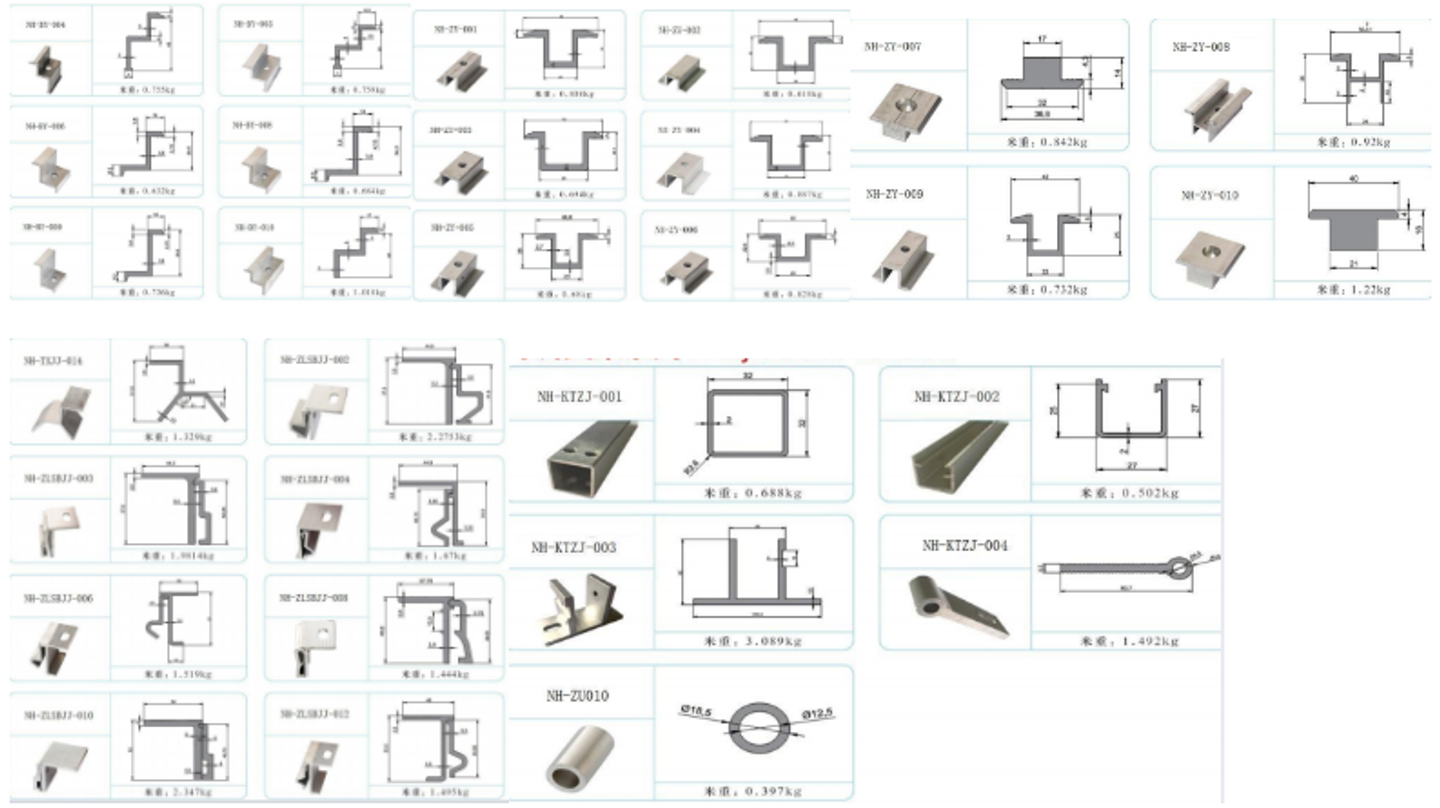

- Products

- Nuoheng - Bending Sheet Metal

Nuoheng - Bending Sheet Metal

Bending(Bending)-sheet metal under Bending machine die or mould,under the pressure of the first through the elastic deformation,and then into the plastic deformation,in the initial stage of plastic Bending,the plate is bent,freedom as the upper die or mould pressure on sheet metal,sheet metal and die of V type groove surface gradually rely on tight,and radius of curvature and Bending arm also gradually become smaller,continue to pressure until the cessation of stroke,lower die and the plate at 3 o`clock on full contact closely,at this time to complete a v-shaped Bending,is commonly known as Bending.

The factors affecting the rebound are analyzed as follows. Related to material properties.Under the condition of the same mold and the same material thickness,the size of springback is compared as:SUS>Al BBB>CC.

Under the condition of the same mold and the same material,the springback amount of thin plate>. With the same material bending inner arc radius R larger,the amount of rebound is larger. the greater the bending pressure,the smaller the amount of rebound.