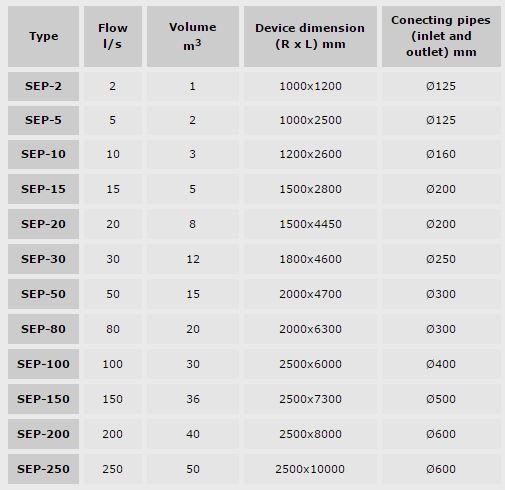

Oil Separators and Oil Derivatives Separators

Oil and oil derivatives separators are used for purification of wastewater from rain drainage for all areas exposed to rainfall and with bigger quantity of residue, such as traffic routes, squares, parks, gas stations, car repair shops, garages, industrial plants, etc. Outlet of purified water is done in natural recipient or sewage system.

- Separators are produced according to the European normative EN858.

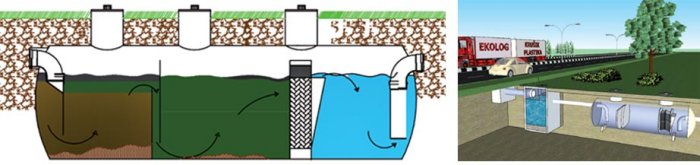

- They consist of sedimentation segment and part with coalescing filter.

Sedimentation tank is equipped with elements for directing the flow and prevention of water whirpools from forming. That way sedimentation of hard matter is intensified and proper and unhindered separation of oil and oil derivatives is enabled in the next phase of processing.

Coalescent filter for separation of oil and oil derivatives consists of oleophilic, non-rotating, horizontal wavy panels by means of which residual oil is separated.

As soon as a drop of oil touches the surface of the filter it gets separated. Oiled water moves along the wawy panels in different speeds. This results in additional collisions of bigger and smaller drops of oil (possibility of coalessence=merging). Drops become bigger as the result of merging of oil particles, which speeds up their upward movement so due to that they become trapped in the filter from which they are separated by gravity into the oil container.

Separators are made of high density polyethylene (PEHD), by means of spiral winding technology which enables maximum consistency of shape during digging.

This material has many advantages over others:

- It is chemically resistant to most of chemically agressive substances

- Resistant to abrasion, corrosion and electrolytically stable

- Thermo stable (-30°C to +80°C)

- Long lasting, prolonged exposure to atmospheric conditions does not influence functionality of the device (duration of up to 50 years)

- Does not pollute the environment or the content within the device, thus preventing the development of algae and bacteria

- UV stable

- Easy to maintain

- Fitting is quick and easy. There is no need for additional costs related to concrete works, construction of foundation, etc.

- Separator is built into the trench, in stable and stabilised ground, onto a compressed bed of sand or gravel 300mm high.

- Separator is placed onto the bed and then evenly backfilled along the rim with sand or gravel. Compression is done manually or with machines, and it is necessary to conduct it so as not to damage the ends or shield.

- Material for backfilling should be used up to 200mm above the separator vertex, and for the remaining necessary quantity material from excavation may be used.

- More detailed explanation of backfilling and fitting procedures is prescribed by the standard EN1610.

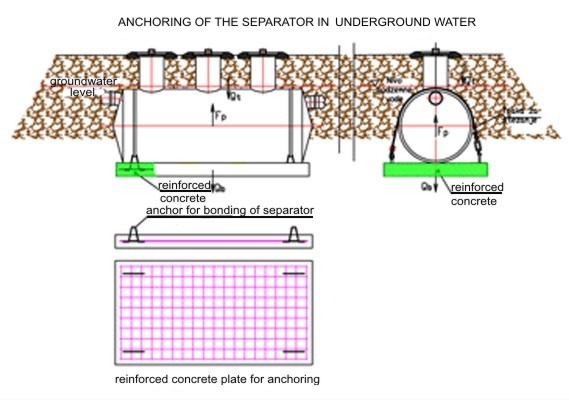

- In case of fitting separators into the soil with underground waters attention must be paid to lift forces.

Maintenance:

After the device is fitted, it is necessary to fill it with water up to the exit level and check the hydraulic flow of water.

Depending on the length of operation, quantity and degree of contamination of the entry water it is necessary to ensure in certain intervals removal of sedimented hard matter from the sedimentation tank and separated oil and ensure its disposal in line with regulations on disposal of dangerous waste.

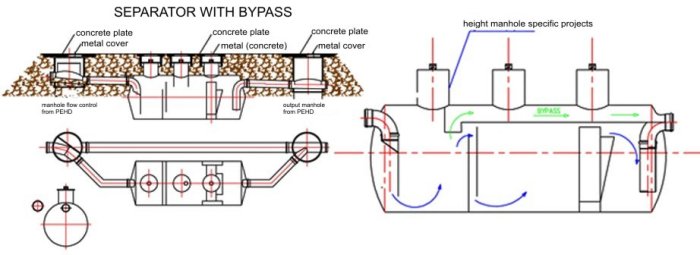

Separators With Bypass:

They are used for treatment of atmospheric waters from large areas (traffic routes, parking lots, squares...) where discountinual occurrences of top flows are possible. That way it is ensured that the first wave of soiled water is introduced into the separator, and the remaining quantity of rainfall from the rinsing area is led over the bypass.

Thus the optimisation of the device capacity is achieved and total investment is significantly reduced.

SEP+Bypass Classic

Classic system of separator fitting with external bypass between two manholes. Acceoting manhole has a special construction which enables distribution and removing the water into the separator and the bypass.

SEP+Bypass Compact

In cases when there is not enough space for placement of the acceptance and exit manhole, this type of separator is used which contains the bypass within the separator construction.

Fitting Method in the Terrain With Elevated Underground Waters:

It is achieved by anchoring the separator for the concrete reinforced slab. Concrete slab dimensions are determined according to the thrust force. Number of places for anchoring, anchor dimensions and strength of the binding straps are dimensioned from stability conditions.