- Home

- Companies

- FRC Systems International - A Sulzer ...

- Products

- FRC - Oil Water Separators (OWS) System

FRC - Oil Water Separators (OWS) System

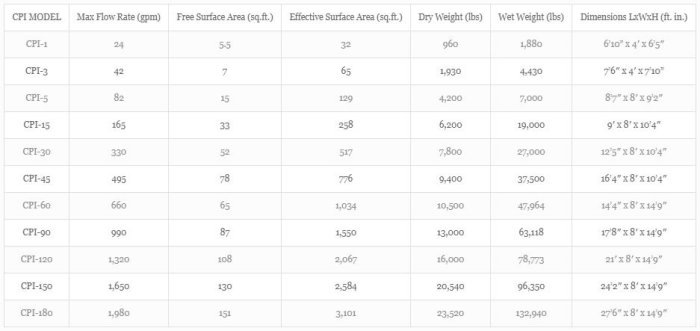

Oil Water Separators (OWS) are used to recover and separate oil from water. For years, API separators have been the de-facto solution for oil separation, but advances in technology and process design have introduced more cost-effective methods. It is upon these technological advancements that FRC has engineered its standard oil/water separator design: the Corrugated Plate Interceptor (CPI). The CPI is a high-rate OWS that comes in 11 pre-engineered sizes, with and without rotating skimmer systems.

Flow Rate

Oil water separators are sized based on hydraulic surface loading rate, or flow rate versus effective surface area in the separation area. An undersized separator can result in undue turbulence and poor separation efficiency.

Design Capacity

Separators have a ceiling on the amount of oily material they can separate over a given duration of time. System designers are responsible for ensuring units are not overloaded with flow or solids.

Wastewater Characterization

A system designer must also understand how free, dispersed, and emulsified oils behave in a gravity separation environment. An analysis of separation behavior will give the most accurate estimated removal efficiency of oil of a particular micron rating.

Separation Media

Manufacturers of oil water separators use different mechanisms to accelerate the separation process, each with its own unique performance characteristics. The right media for the application depends on the volume and type of wastewater, project budget, and preferred maintenance schedule. No one media is perfect for all projects, though a couple designs perform better than the rest.

Use of Surfactants

Soaps and detergents used to clean equipment are specially formulated to emulsify and disperse oil into water. Chemical emulsions caused by surfactants take significantly longer to separate in an oil/water separator, if they can be removed at all. Without the correct process design, chemically emulsified oils will pass through the separator and remain in the effluent.

Conceptually, the oil/water separation process is simple – allow oily water to sit undisturbed long enough and eventually oil globules will begin to stratify, sink or float – but this passive approach is often too slow to work in real world applications where flows and loadings are always changing.

Proper oil water separator design proactively accelerates this separation process, allowing for continuous oil separation and recovery that matches the needs of industrial facilities.

The CPI is designed with corrugated plates to allow for high hydraulic loading capacity in a small footprint. Floating oils are removed from the water’s surface via an overflow channel on a static pipe skimmer.

The V-shaped bottom and automated auger help remove settled sludge.

CPI with Rotating Skimmer

In instances where wastewater is laden with particularly viscous or heavy oily solids, the CPI is fitted with a rotating flight-and-chain skimmer to help scrape oils off the water’s surface. In this way the CPI can manage a higher hydraulic loading rate.

These CPI’s are fitted with a skimmed sludge hopper for intermittent removal via sludge pump.