O.M.P. Officina Meccanica Pignotti srl

- Home

- Companies

- O.M.P. Officina Meccanica Pignotti srl

- Products

- OMP - Model FP 1000 - Filter Press

OMP - Model FP 1000 -Filter Press

Main technical features: N1 Frame made of HEA 200 beams joined by welds. N°2 Box-like fixed heads made in thick sheet, joined by TIG welds. N°1 Mobile head having the same characteristics of the fixed ones, sliding on treated steel castors and guides made from the tie rods that connect the fixed heads. N°1 Hydraulic cylinder Ø200 mm. N°1 Hydraulic gearbox, 7.5 kW and maximum pressure of 200 Bar. N°1 Laminar bundle consisting in a minimum of 6 plates with a maximum pressure of 16 bar, made in polypropylene and coated with polypropylene filtering elements. Plants can be customised in terms of number of plates fitted on the laminar bundle.

Most popular related searches

water treatment plant

polypropylene filter element

water storage system

water booster system

water storage

water treatment

pipeline cleaning

water discharge

water pipeline cleaning

polypropylene filter

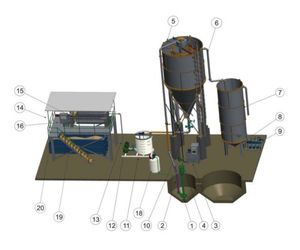

Layout of water treatment plant:

Legenda

- Clarifier feeding pump

- Standard clarifier feeding pipeline

- Flocculant automatic unit / or manual

- Flocculant dosing pump & pipeline

- Clarifier

- Clean water storage feeding pipeline

- Clean water storage unit

- Standard clean water discharge

- Clean water booster system

- Standard sludge discharge

- Sludge homogenizer

- Filterpress feeding pump

- Filterpress feeding pipeline

- Filterpress perimetral railing

- Filterpress

- Electrical board

- Coagulant unit

- Filterpress access stairs

- Filterpress Platform structure

- Width: 1500 mm

- Length: 4700mm

- Height: 1700 mm

- Net weight: 1700 kg

- Adsorbed electric power: 8 kW

- Consumption of compressed air: 100Lt/h

- Working pressure: 180 Bar

- Purified water per cycle: 29 Lt/Plate