- Home

- Companies

- Optimarin AS

- Products

- Optimarin - Optimarin Ballast Water ...

Optimarin - Optimarin Ballast Water Treatment System (OBS)

This cabinet contains the Programmable Logic Controller (PLC) that controls and logs all executed operations in the Optimarin Ballast Water Treatment System.

The Optimarin Control Panel has undergone a major upgrade with new high-end performance CPU and touch screen. With the latest control system technology implemented, we now bring our BWTS into the new technological era. With increased processing power and response time, we can now control, monitor and share information in a more optimized manner. All this is available at the new touch panel or remotely with cloud-based data acquisition for central easy overview (OptiLink)

- Custom made with improved user-friendly interface – developed by Optimarin

- New 9″ high-end performance widescreen TFT display with touch operation.

- New high-end performance Siemens CPU 1516 series

- Interface with the ship’s main control systems (with data bus or digital I/O)

- Supports the new OptiLink solution with cloud-based data acquisition for central easy overview ( OptiLink sold separately)

- Supports connection to vessels GPS for position and time synchronization

- Supports PROFINET (Industrial Ethernet) and PROFIBUS (Process Field Bus)

- Logging in accordance with IMO and USCG requirements

- Operation log, alarm list and operation data can easily be extracted from the touch panel with just a click to an inserted USB-stick or to cloud (OptiLink).

- Easy import and export functionality of operation parameter configuration without service onboard

- Supports all Optimarin additional features (PMS integration, Interlock, fresh water filling +++)

The Optimarin Control Panel has undergone a major upgrade with new high-end performance CPU and touch screen. With the latest control system technology implemented, we now bring our BWTS into the new technological era. With increased processing power and response time, we can now control, monitor and share information in a more optimized manner. All this is available at the new touch panel or remotely with cloud-based data acquisition for central easy overview (OptiLink)

- Custom made with improved user-friendly interface – developed by Optimarin

- New 9″ high-end performance widescreen TFT display with touch operation.

- New high-end performance Siemens CPU 1516 series

- Interface with the ship’s main control systems (with data bus or digital I/O)

- Supports the new OptiLink solution with cloud-based data acquisition for central easy overview ( OptiLink sold separately)

- Supports connection to vessels GPS for position and time synchronization

- Supports PROFINET (Industrial Ethernet) and PROFIBUS (Process Field Bus)

- Logging in accordance with IMO and USCG requirements

- Operation log, alarm list and operation data can easily be extracted from the touch panel with just a click to an inserted USB-stick or to cloud (OptiLink).

- Easy import and export functionality of operation parameter configuration without service onboard

- Supports all Optimarin additional features (PMS integration, Interlock, fresh water filling +++)

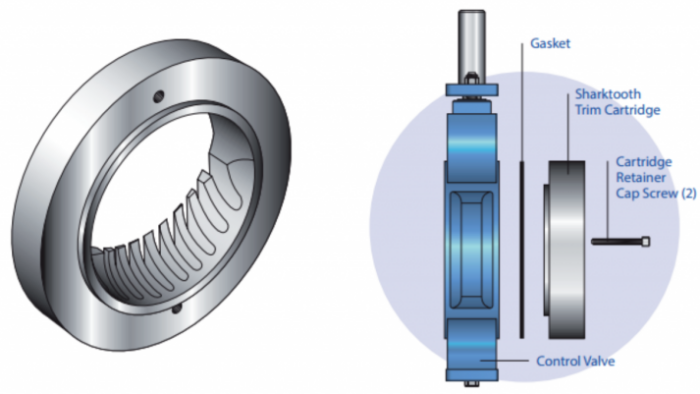

Optimarin has the pleasure of introducing a new type of control valve: Electric Flow Pressure Valve. The electric FPV will provide OBS with the latest in control valve innovation, technology and valve acoustics.

- Small (DN350: 193mm)

- Light (DN350: 130kg)

- Building material

- Butterfly valve with rubber seat, bronze-alu disc

- Flow control element in stainless steel

- Electrically actuated

- Control speed fixed in actuator

- Fluctuating pressure has no impact on control

- Prepared for OptiFlow

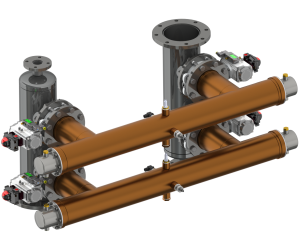

The UV lamps emits short wave radiation into the water. This will expose any organisms or pathogens with a high dose of UV light. The UV-exposure will kill or inactivate the remainder of plankton as well as any bacteria/viruses.

The UV System consists of two manifolds with one or more UV chambers installed in parallel. The UV chambers are fabricated from a single CuNi Fer 90/10 DN150 pipe with a wall thickness of 3mm. Each chamber can treat up to 167 m³/h ballast water using a high-power UV lamp. The maximum effect for each UV-lamp is 35kW.

- High power UV for the efficient killing or inactivation of organisms, bacteria and pathogens in ballast water

- One UV lamp per chamber

- Optimized for minimum maintenance and ease of operation.

- No moving parts and self-cleaning.

- No chemical cleaning needed.

- UV and temperature sensor in each chamber.

- Standardized UV chamber, installed in parallel on a single manifold for higher flows.

- Maximum flow per chamber: 167m³/h in all modes

- Holding time IMO mode: No holding time

- Holding time USCG mode: 2 hours

The purpose of the filter is to remove particles from the seawater during ballast or stripping operations. Any particles larger than 40 μm is stopped by the filter mesh. The ballast water treatment system is designed so that the filter is bypassed during de-ballast operations. The filter has an automatic self-cleaning function by reversing the flow direction and flushing the untreated water back into the sea.

Key features include

- Removes larger particles and organisms

- Low pressure loss of only 0.1 – 0.5 BAR

- Bypassed during de-ballasting

- Automatic back flushing and are self-cleaning

- Boll & Kirch

- Basket type

- 25 μm

- Filtrex

- Basket type

- 20 μm