- Home

- Companies

- Ozone Research and Applications India ...

- Products

- Oraipl - Self-Sustained Auto Backwash ...

Oraipl - Self-Sustained Auto Backwash Iron Removal Plants

Empanelled by the Government of India under Jal Jeevan Mission & Swachh Bharat Mission. At ORAIPL, we take pride in manufacturing, installing, and maintaining Self-Sustained Iron Removal Plants (SS-IRP) – a cutting-edge, power-free system designed to purify groundwater contaminated with iron (Fe), manganese (Mn), and arsenic (As). Our innovative design has been empanelled by the Ministry of Jal Shakti, Government of India, under the National Jal Jeevan Mission (JJM) and Swachh Bharat Mission (SBM) as a recommended and innovative technology for drinking water purification.

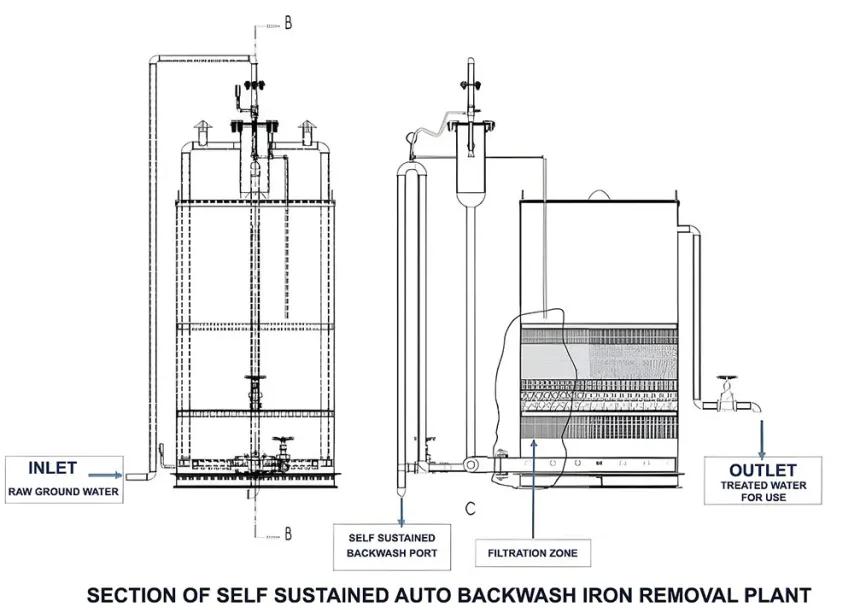

How the ORAIPL Self-Sustained Iron Removal Plant Works

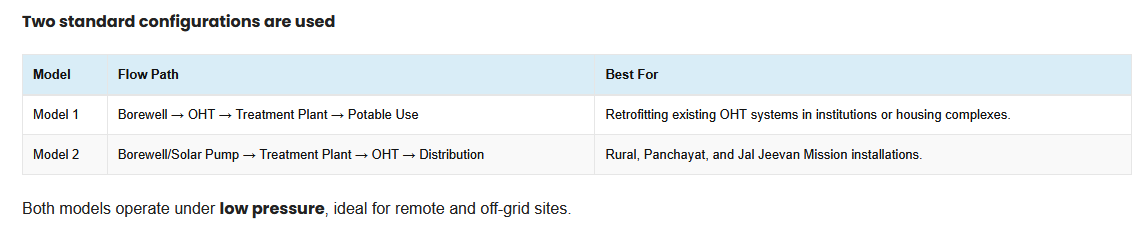

ORAIPL’s Self-Sustained Iron Removal Plant (SS-IRP) is a chemical-free, power-free, and automatic filtration system that combines vacuum aeration, extended aeration, and multi-stage filtration to remove dissolved iron, manganese, and arsenic from groundwater.

The plant functions entirely through gravity flow or solar pumping, with no electricity, chemicals, or manual intervention.

Step-by-Step Process Overview 1. Raw Water Collection

Raw water from a borewell or tube well enters the system through natural pressure or a solar-operated pump.

Depending on the infrastructure, it can be configured as:

-

Inlet from borewell to treatment unit, or

-

Inlet from Overhead Tank (OHT) to treatment plant.

This flexibility allows installation either upstream or downstream of storage tanks — suitable for village water systems, institutions, or industrial setups.

2. Induced Vacuum Aeration System

In this patented stage, the plant uses vacuum-induced aeration to create fine microbubbles ( without compressors or blowers.

These bubbles provide high oxygen transfer, oxidizing:

- Ferrous iron (Fe²?) into insoluble ferric hydroxide (Fe³?),

- Manganese (Mn²?) into MnO2 precipitates, and

- Arsenic (As³?) through co-precipitation with iron flocs.

It also eliminates hydrogen sulfide, improving the water’s taste and odor — all without power or chemicals.

3. Extended Aeration & Reaction Chamber

Water then flows into a reaction zone, where extended aeration ensures complete oxidation and precipitation of iron and manganese particles.

The process allows suspended solids to form stable flocs that can be easily filtered, ensuring consistent water quality even for sources with high iron levels (up to 20 mg/L).

4. Multi-Media Filtration Unit

The oxidized water passes through a multi-layer filter bed, consisting of:

- Gravel base – supports the media bed.

- Coarse sand – removes large suspended solids.

- Manganese dioxide-coated media – catalytically oxidizes and traps metals.

- Zeolite or activated alumina – adsorbs trace contaminants and arsenic.

- Fine sand layer – polishes the water for clarity.

The output is clear, odor-free water meeting IS 10500:2012 drinking water standards.

5. Automatic Hydraulic Backwash

As the filter becomes loaded, a hydraulic head differential triggers an automatic reverse flow, flushing the impurities out through the drain.

This process uses the system’s own pressure — no motors, pumps, or valves — making it completely self-sustaining and maintenance-free.

6. Treated Water Storage & Distribution

Finally, the treated water flows into the Overhead Tank (OHT) or distribution line.

Why Choose ORAIPL

- Government of India–Empanelled under Jal Jeevan & Swachh Bharat Missions.

- Made in India, engineered specifically for Indian groundwater challenges.

- End-to-End Solutions – Design, installation, commissioning, and O&M.

- Proven performance validated by national authorities.

- Sustainable technology aligned with India’s Har Ghar Jal vision.

ORAIPL’s Iron Removal Plants are already serving multiple communities, institutions, and rural water schemes across India—bringing safe, sustainable water access to thousands.

- Government of India–Empanelled Technology under Jal Jeevan Mission.

- Completely Self-Sustained – No power, no operator, no chemicals.

- Auto Backwash System – Maintenance-free operation for years.

- Capable of High Iron Loads – Treats up to 20 mg/L Fe.

- Removes Mn, As, and Odor for superior water quality.

- Long Service Life – Rugged design suitable for village and institutional use.

- Eco-Friendly & Low Cost – Zero operational energy, zero chemical waste.

1. Rural & Panchayat Water Supply Schemes

Our self-sustained plants are tailor-made for village-level water supply systems under the Jal Jeevan Mission.

They can be installed at borewell outlets, overhead tanks, or distribution points to deliver safe, iron-free water to every household—without depending on electricity or skilled manpower.

Typical use cases:

-

Gram Panchayat and community drinking water schemes.

-

Borewell-fed handpump and OHT systems.

-

Jal Jeevan Mission projects in iron-rich states (Odisha, Chhattisgarh, Jharkhand, West Bengal, Assam, Madhya Pradesh, etc.).

2. Schools, Hospitals & Government Institutions

These facilities often depend on borewell water, which may contain dissolved iron and manganese.

Our plug-and-play systems ensure safe, odor-free drinking and cooking water, protecting students, patients, and staff from iron-related water issues.

3. Industrial & Commercial Applications

Industries such as food processing, textiles, beverages, paper, and pharmaceuticals require low-iron process water to avoid staining, scaling, and production losses.

ORAIPL’s self-sustained plants provide high-quality iron-free water with minimal maintenance and no recurring costs.

4. Housing Societies & Townships

In peri-urban and rural housing clusters where groundwater is used, iron often causes discoloration and plumbing damage.

Installing an ORAIPL Iron Removal Plant ensures clear, odorless water, protecting fixtures and improving living standards.

5. Agricultural & Livestock Use

Excess iron can clog irrigation systems and harm livestock health.

Our systems provide clean, iron-free water for agricultural spraying, dairy, and poultry applications.

Parameter - Description / Range

- Treatment Capacity: 1,000 to 100,000 LPH (custom-built for each site)

- Target Contaminants: Iron (Fe), Manganese (Mn), Arsenic (As), Hydrogen Sulfide (H2S), and suspended solids

- Iron Removal Efficiency: Reduces iron from up to 20 mg/L to below 1 mg/L

- Manganese Removal Efficiency: Reduces Mn from up to 3 mg/L to below 0.3 mg/L

- Arsenic Removal Efficiency: Reduces As from up to 0.05 mg/L to below 0.01 mg/L

- Operation Type: Fully self-sustained — no external electricity or chemicals required

- Power Source: Works on gravity flow or solar pump — no grid power needed

- Filtration Process: Multi-layer bed filtration with catalytic and adsorption media

- Backwash System: Automatic self-backwash using hydraulic pressure differential

- Chemical Use: 100% chemical-free — no chlorine, alum, or oxidants required

- Maintenance: Minimal — periodic visual inspection only

- Installation Options: ? From borewell to treatment → to OHT → distribution ? From solar pump → to treatment → to OHT

- Design Life: 15+ years with routine maintenance

- Compliance: Meets IS 10500:2012 (Indian Drinking Water Standards)a