Dosch - Orifice Plates for Pressure Tapping Fittings

Orifice plate according to ISO 5167 – Your reliable and cost-effective choice for flow measurement. Rely on orifice plates according to ISO 5167 for precise flow measurement of fluids in pipelines. An orifice plate is characterized by its sharp-edged inlet, generating a defined differential pressure used to calculate the volumetric or mass flow rate. The orifice plate coefficient of discharge accounts for all losses that occur when a fluid passes through the plate. Thanks to their standardization based on the ISO 5167 standard, our orifice plates offer accurate and reproducible measurements, as well as easy comparability and interchangeability. Our standard orifice plate is a 65mm orifice plate.

Whether for process monitoring, energy optimization, flow metering, or ensuring process stability through precise flow control – a Dosch orifice plate is your reliable and economical solution. Trust in our quality and precision!

- High Precision: Our orifice plates according to ISO 5167 ensure accurate flow measurements.

- Cost-Effective Solution: An orifice plate is a popular, economical choice for flow measurement of fluids in pipelines.

- Customizable: Our orifice plates are tailored exactly to your requirements.

- Decades of Experience: Benefit from our long-standing expertise for the highest quality.

- Reliable Availability: We ensure reliability thanks to experienced manufacturing and high production capacity.

Experience the right solutions for precise and reliable flow measurement of fluids in pipelines with our three different versions. We offer a standard orifice plate with single tapping, a ring chamber orifice plate, a orifice plate corner tapping, and a weld-in orifice plate. Our orifice plates are highly flexible and can be customized with additional tappings for redundant measurements or for use at high/low temperatures and high pressure.

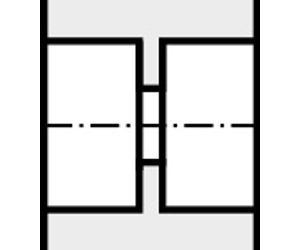

One-piece mounting ring with non-replaceable measuring insert. The easy-to-clean individual bores are particularly advantageous for media that resinify or build up, or for systems that do not remain in operation continuously.

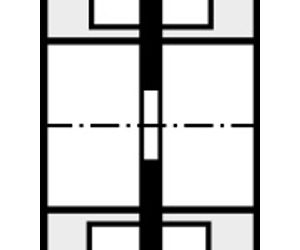

Two-piece frame ring with ring chamber removal and exchangeable measuring insert. The ring chamber removal creates a good average value of the plus and minus pressure. This produces a smoother measuring signal. This generates a quieter measurement signal.

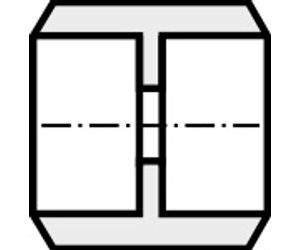

Standard orifice plates – whether with annular chamber (EBLA 800) or without (EBLB 800) – can also be offered as weld-in differential pressure devices. These are used in the high-pressure and high-temperature range.

We are happy to expand the weld-in orifice plate with a welded-on inlet and outlet pipe to meet the requirements of the calculation standard.

Always ready for use across various industries: Our orifice plates are widely used wherever precise flow measurements are required. In the energy industry, they measure steam, water, and gas flows for efficiency monitoring, while an orifice plate monitors crude oil and gas flows in the oil and gas industry. They are also indispensable in the chemical and petrochemical industries, as well as in water and wastewater management. In the pharmaceutical and food industries, they are used to monitor hygienic processes.

Typical versions of the pressure nozzles are:

- smooth sockets for screw connections

- Welding socket

- Threaded socket

- Sockets with flanges

- according to DIN EN 61518 (compact)

Depending on the application, the measurement uncertainty is approx. 0.5% – 1.2% of the flow coefficient.

EquipmentStandard orifices can be equipped with shut-off valves and/or valve blocks. Condensate vessels are recommended for steam applications.