- Home

- Companies

- West Salem Machinery Co. (WSM)

- Products

- WSM - Oscillating Screens

WSM - Oscillating Screens

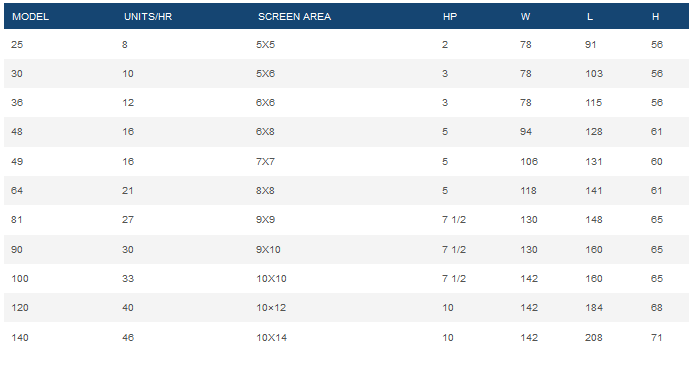

For high volume chip screening, bark screening, or precise classification of sawdust and shavings for animal bedding, the WSM`s Oscillating Screen is a favorite across a variety of industries. With a screen area up to 12′ x 20′ and production capacities from 8 to 80 units per hour, WSM`s Oscillating Screen provides as much capacity as you need. All WSM Oscillating Screens are available with a full range of options and are designed to meet the individual requirement of your business.

- Wood Chips

- Bark

- Mulch

- Particleboard Furnish

- Sawdust/Shavings

- Trim Ends & Edgings

Years of field experience have gone into the features that make your operation easier to run and your screen easier to maintain.

- Readily accessible belt drive assembly for easy maintenance

- Adjustable tilt basket assembly maximizes production capacity

- Counterweighted drive for smooth, balanced operation

- Centralized drive lubrication system, providing safe access for lubrication during operation

- Easily replaceable heavy gauge steel screens. Choose perforated or wire mesh screens with variable wire diameter as required for accurate material classification.

- Optional ball deck assemblies prevent wet material from blinding screen openings.

Let us know what material you’re working with, and we’ll work together to configure your screen for maximum productivity

Efficient Effective

WSM FLAT OSCILLATING SCREENS PROVIDE EFFICIENT AND EFFECTIVE CLASSIFICATION OF A VARIETY OF WOOD MATERIALS.

From high volume chip screening to precise classification of particleboard furnish, to bark screening for mulch - these screens offer proven performance and reliable, low maintenance operation in demanding environments. All WSM screens are constructed using the highest quality materials and manufacturing techniques.

Smart Design Features

DESIGNED AND ENGINEERED WITH FEATURES TO MAKE YOUR JOB EASIER.

Readily accessible belt drive assembly for easy maintenance, adjustable tilt basket assembly maximizes production capacity, counter-weighted drive for smooth and balanced operation, centralized drive lubrication system provides safe access.