E-mail: net@techinservice.com.ua

Phone: +380 (44) 468-93-11

Adress: Makiivs`kyi Lane, 1 , Kyiv , 04114 Ukraine

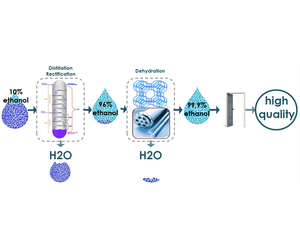

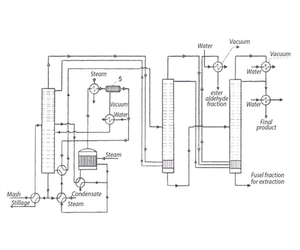

Before the appearance and spreading in the industry the membrane dehydration method, which allows to dehydrate ethanol without adversely affecting its physical, chemical and organoleptic properties, the purification of ethanol from impurities on a classical mash-rectification units (MRU) was reduced to the separation (rectification) of the not binary system of ethanol-impurity (in cases of dehydrated ethanol) but the triple system - water-ethanol-impurities. The main reason for the "non-standard behavior" of impurities to ethanol and as a consequence of the complexity of their isolation is the presence of water bonds in ethanol and impurities. The change in volatility and the rectification factor of impurities at different concentrations of ethanol necessitates the use of additional water supply (hydroselection, extraction, etc.) in certain sections of the MRU switchgear, and in spite of the temperature peculiarities of triple azeotropes (water-ethanol-impurities) it allows to increase the volatility and the rectification factor of impurities - head, tail, intermediate and final ones.

As a result of dehydration of ethanol during its purification (separation), the intermediate and final impurities lose their specific (double) properties and behave either as head impurities (in case of OWERTech technology – isolation on a methanol column) or as tail impurities (in case of OWERTech technology – isolation on a fusel-oil concentrating column), which is confirmed by laboratory and industrial tests and production implementation.