- Home

- Companies

- Ozone Research and Applications India ...

- Products

- Oraipl - Model PSA - Oxygen Generators

Oraipl - Model PSA -Oxygen Generators

Ozone generators require a steady and pure supply of oxygen for stable operation and maximum yield. ORAIPL’s PSA Oxygen Generators provide oxygen with 93 ± 3% purity, ensuring optimum performance of both Plate-Type and Tube-Type Plasma Ozone Generators. Our PSA systems are built on robust engineering principles, delivering consistent flow rates, high concentration, and long service life, making them suitable for laboratories, pilot plants, and full-scale industrial applications.

Why Choose ORAIPL PSA Oxygen Generators

- On-Site Oxygen Production → Eliminates reliance on oxygen cylinders or liquid oxygen.

- Continuous, Reliable Supply → No risk of interruption due to supply chain issues.

- High Energy Efficiency → Lower operating cost compared to cryogenic oxygen.

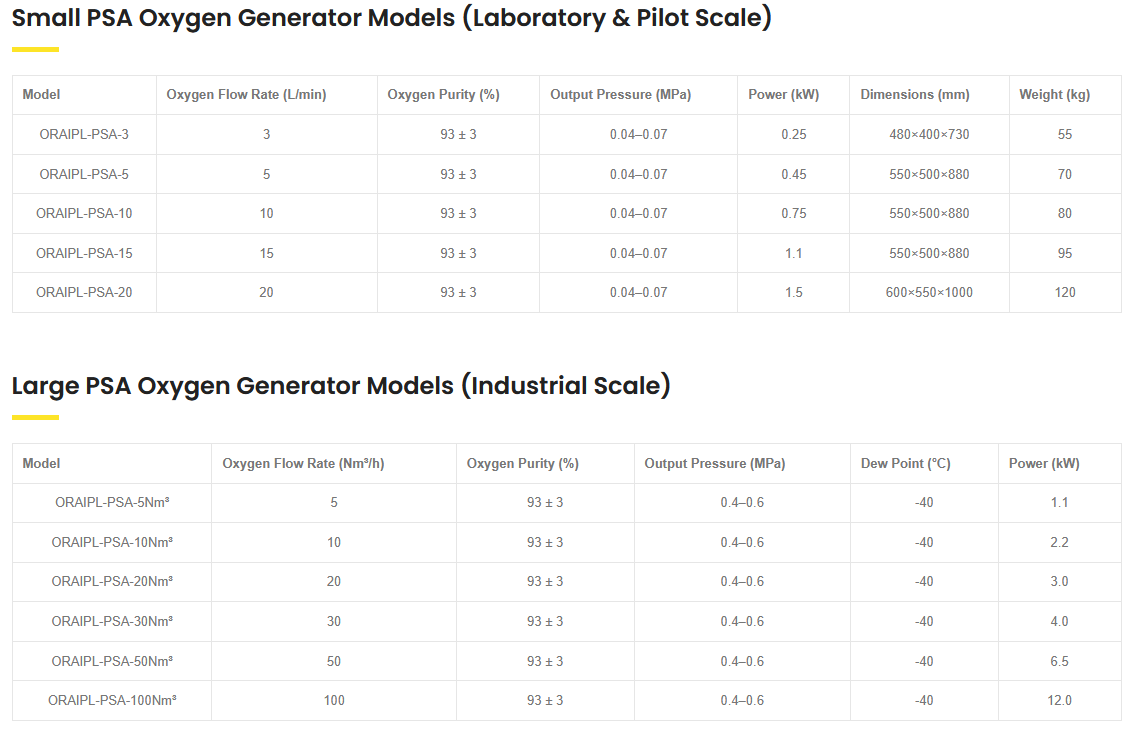

- Scalable Capacity → From small 3 L/min lab units to 100 Nm³/h industrial plants.

- Compact & Modular → Easy integration into existing ozone plants or standalone use.

- Proven Longevity → Molecular sieves with > 10 years lifespan under proper operation.

Technical Working Principle of PSA Oxygen Generators

Pressure Swing Adsorption (PSA) is a physical gas separation process that leverages the different adsorption characteristics of nitrogen and oxygen on Zeolite Molecular Sieves (ZMS).

-

Air Intake & Conditioning

-

Ambient air is compressed (typically 0.6–0.8 MPa).

-

Oil, moisture, and particulates are removed via pre-filters and dryers.

-

-

Adsorption Phase

-

Compressed air passes through a ZMS column.

-

Nitrogen and trace gases are preferentially adsorbed by the zeolite under pressure.

-

Oxygen molecules pass through as the primary product gas.

-

-

Desorption (Regeneration) Phase

-

Once the molecular sieve becomes saturated, the system switches towers.

-

The first tower is depressurized, releasing adsorbed nitrogen back into the atmosphere.

-

The second tower continues oxygen production, ensuring uninterrupted supply.

-

-

Delivery

-

The product gas (oxygen with 93 ± 3% purity) is stored in a buffer tank.

-

Output pressure is typically 0.4–0.6 MPa, suitable for direct connection to ozone generators.

-

- Twin-Tower Adsorption Design → Continuous supply with automatic switching.

- High-Efficiency Molecular Sieves → Premium ZMS with long service life and stable performance.

- Integrated Skid-Mounted Systems → Compact footprint, plug-and-play operation.

- PLC/Controller Based Automation → Minimal operator intervention, full monitoring of pressure cycles.

- Optional Oxygen Storage Tanks → For demand balancing in large ozone plants.

- Purity: 90–95% oxygen (93 ± 3% standard).

- Pressure: 0.4–0.6 MPa output, optimized for ozone generators.

- Dew Point: Typically -40 °C, ensuring moisture-free oxygen supply.

- Energy Efficiency: 0.6–1.5 kWh per Nm³ of oxygen, depending on model size.

- Cycle Time: Adsorption/desorption cycles every 30–120 seconds, controlled automatically.

While PSA oxygen generators are often paired with Plasma Ozone Generators, they are also widely used in:

- Healthcare & Medical Oxygen Systems (hospitals, clinics, oxygen therapy).

- Aquaculture & Fisheries (pond oxygenation, RAS systems).

- Industrial Combustion (glass, ceramics, metallurgy).

- Wastewater & Sewage Treatment (enhancing aerobic processes).

- Food & Beverage Processing (oxygenation for fermentation and packaging).