Jimco - Model Flo-D Mini Mark 2 -Ozone & UV Surface Disinfection System

The environmentally friendly disinfection machine FLO-D Mini Mark 2 has the unique UV-C & Ozone technology which impacts the performance significantly. Disinfect with more than 99,99% with FLO-D Mini Mark 2 without filters, chemicals, or water. The machine is easy to move around and can be used in multiple locations. You will also be able to data log your ozone & UV-C surface disinfection, so you have documentation for your treatment.

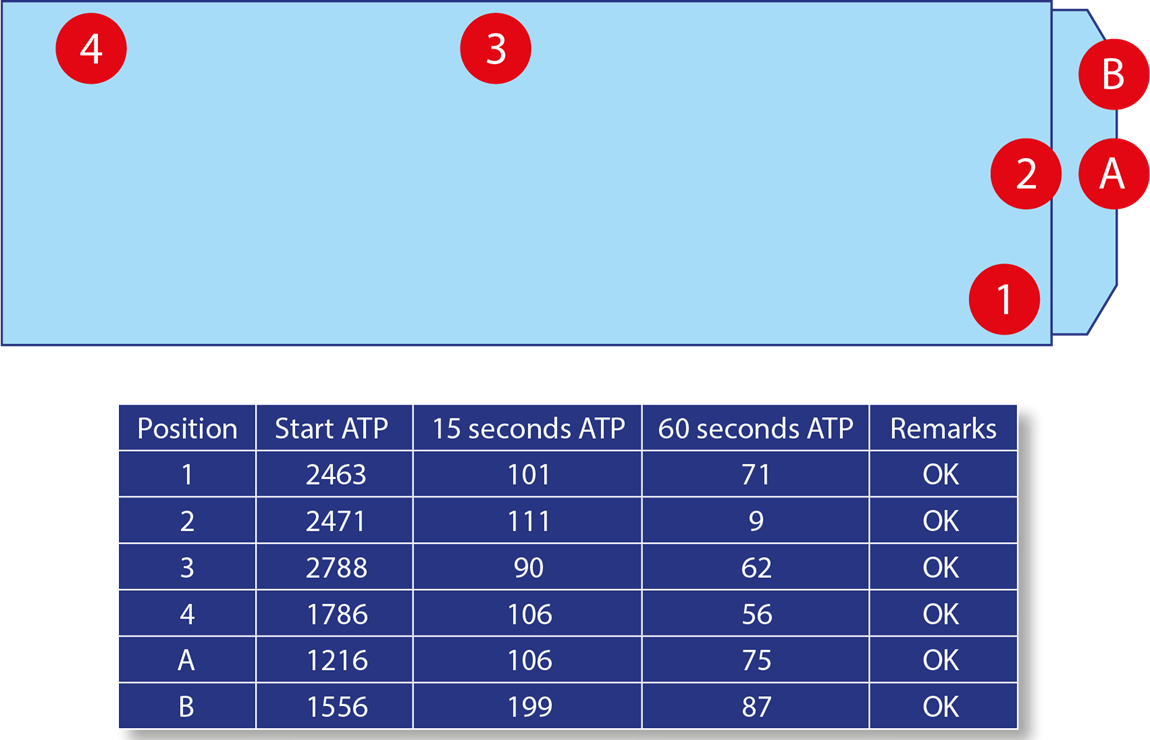

We always test our products, so you get the best quality product, but we also test for the reduction of bacteria to see the huge impact the FLO-D Mini Mark 2 does with UV-C and ozone surface disinfection

Save money with the UV-C & Ozone surface disinfection treatment

For the food industry, disinfection has always played an important role. For example, ethylene, mold and yeast shorten the time in which the food stays fresh. In the fruit industry, among other places, mold and yeast growth is a tough opponent affecting product lifespan. To keep the food fresh, you can use the FLO-D Mini Mark 2 to reduce the bacteria, mold and yeast in the cold storage, or in any room, with up to 99,99%. The reduction will optimize the lifespan of e.g. fruits and it will help revolutionize the way fruit is stored and transported.

REMARKABLE UV-C SURFACE DISINFECTION RATES:

- Staphylococcus aureus: 99,973 %

- Candida albicans (yeasticidal): 98,741%

- Enterococcus hirae: 99,149%

- Escherichia coli: 99,880 %

- Pseudomonas aeruginosa: 99,898%

- Modified vaccinia virus Ankara (MVA): >99,99%

- Disinfects in corners, chinks, ventilation ducts and surfaces

- No manual procedures

- No use of chemicals or water

- PLC controlled unit with datalogging, for documentation

Due to increasingly higher hygiene demands in the food processing industry etc., the use of UV-C light to eliminate microorganisms e.g. bacteria, fungi, and viruses, is becoming more and more commonly used.

Using UV-C light to eliminate microorganisms in the air is a technique that has been known for decades. UV-C light reduces the total amount of microorganisms in the room by breaking the DNA bonds in the organisms.

Using UV-C Technology, JIMCO is specialized in the elimination of microorganisms and odors.

A minor contamination with microbiology may result in a faulty commodity – in consequence, it can be an expensive affair for the company. To avoid this, a steadily increasing number of companies decide to use UV-C surface disinfection.

Depending on the calculated UV-C dosage, a kill rate of 99.9% of all microorganisms may be achieved. Together with the PLC-control, special UV-C sensors developed by JIMCO, ensure that the UV-C light is 100% effective to surface disinfection.

Efficient disinfection – without manual procedures, chemicals or water

With the introduction of the UV-C-based disinfection of surfaces, we now add yet another field of application to our patented UV-C technology, which has been awarded the EU Environmental prize and which since 1993 has been used in self-produced air cleaners – systems which are used for removing obnoxious smells, improving the indoor climate as well as reducing the danger of fire and infection hazards.

Now it is possible to use the UV air disinfection systems, which would normally require a manual treatment, involving a large number of advantages for the operating economy, the environment as well as the work environment.

Why choose an automatic Surface disinfection?- You will avoid time-consuming manual disinfection with water and chemicals

- You will save liters of water by the thousand as well as energy for heating and drying

- You will disinfect more efficiently in corners, chinks and ventilation ducts, cooling surfaces.

- You will avoid strong chemicals, which have an impact on the environment and work environment

- Avoid an environmentally harmful release of chlorinated wastewater

- Fast pay back

In most environments, the system will provide savings on manpower, water, and heat in amounts that are so high that the repayment period will only last approximately one year.

The surface disinfection module can with advantage be used with JIMCO’s ozone & UV-C surface disinfectionthat are typically installed in connection with existing ventilation systems. In this way, the customer will have a total solution, which cleans the air in the production rooms during working hours – and disinfects all surfaces after closing time, when the daily cleaning of machines and surfaces is complete and there are no longer any people in the room.

The start-up can take place automatically via a foregoing programming, e.g. when a given process is ended, or manually by pressing a button when the last person leaves the room. Besides production rooms, the solution can with great advantage be applied in i.a. cooling and storage rooms, laboratories as well as in the health sector for the surface disinfection of bed units, etc.

Advantages for the FLO-D Mini Mark 2 for UV-C surface disinfection

- PLC controlled units with datalogging, do not require additional manpower

- Access point for wireless connection by smartphone or tablet

- Loud alarm before treatment start – in 8 different languages

- New weekly treatment program mode

- Moisture and temperature meter

- Save liters of water by the tons as well as energy for heating and drying

- Disinfect more efficiently in corners, chinks and ventilation ducts, cooling coils and surfaces

- Avoid strong chemicals, which have an impact on the environment and work environment

- Avoid an environmentally harmful release of chlorinated waste-water

- Avoid time-consuming manual disinfection with water and chemicals

The FLO-D Mini Mark 2 produces Ozone by draining the air in the room through the system’s UV-C chamber where oxygen O2 contained in the air is converted to ozone O3. The ozone then blows out and spread into the room.

- Ozone treatment in 3 hours with FLO-D Mini Mark 2 would reduce the amount of organic matter in which bacteria thrive and reproduce.

- That, without other means, we get an ozone flow through evaporating the unit, so that there is also a reduction of organic matter.

- Reduction or removal of odors.

There was a significant reduction of fish smell after treatment, the trailer was left in the workshop overnight, which without ozone treatment usually means no one can keep the smell of fish out at the workshop and it is normal practice to pull chees / fishing trailers out at night.

Test settings for the FLO-D Mini Mark 2: Blower speed 80%, Ozone measurement upper ozone limit 9 ppm lower limit 8 ppm - hours ON - 03 hours 00 minutes.

- Food Industry

- Municipal facilities

- Hospitals

- Sport facilities

- Biogas plant

- Toilets

- Hatchery

- Locker Rooms

- Canteens

- Food Productions

- Seed Disinfection

- Delicatesses

- Carriers

- Reefer containers

- Etc.

- UV Lamp: 8 pcs. 70 Watt

- Quartz sleeve: 8 pcs. (in cold storage)

- Power supply EU: 1x230V + PE 50/60Hz, 10A

- Power supply US: 1x115V + PE 50/60Hz, 10A

- Power supply EU: 1x230V + PE 50/60Hz, 10A

- Consumption EU: 640 watt Consumption US: 685 Watt

- Display: Proface PLC, color panel

Room-volume

- Disinfection: Up to 314 m3

- Odor treatment: Up to 1.258 m3

Mesurements

- Height: 1150 mm

- Width: 560 mm

- Depth: 890 mm

- Weight: 59 kg