- Home

- Companies

- Hydroflux Pty Ltd

- Products

- Hydroflux Epco - Model RoadTrain - ...

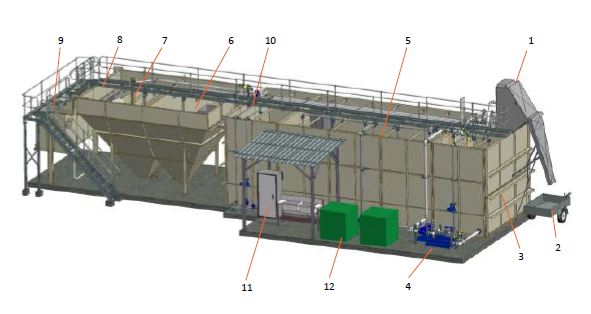

Hydroflux Epco - Model RoadTrain -Package Sewage Treatment Plant

Roadtrain packaged plants by Hydroflux Epco have been in operation since the late 1960’s. Applications include sewage treatment for towns, villages, resorts, mine sites and gas exploration fields. The systems are designed to operate with a minimum level of site attendance and are ideally suited to remote locations.

Roadtrain packaged plants are available in three process designs as follows:

- Extended Aeration Activated Sludge Process

- Rotating Biological Contactor

- Membrane Bioreactor

The selection of the most appropriate process is dependant upon the available footprint, site location and discharge requirements.

- Extensive expertise with specific designs for remote locations

- Robust construction, proven throughout Australia, the Middle East, Pacific Islands and South East Asia

- Unattended operation

- High discharge water quality (options for Class A reuse)

- Special bolted designs for very remote locations

- Easily shipped to anywhere in the world

- Remote monitoring available with HyConnect®

- Towns and Villages

- Resorts

- Mining Accommodation Camps

- Oil Exploration Fields

- Development Estates

- Inlet Screen

- Screenings Trailer

- Balance Tank

- Forward Flow Pumps

- Aeration Tank

- Clarifier

- Airlift Driven Sludge & Scum Returns

- Effluent Trough

- Chlorine Detention Tank

- Waste Activated Sludge Digester

- Control Panel

- Blowers

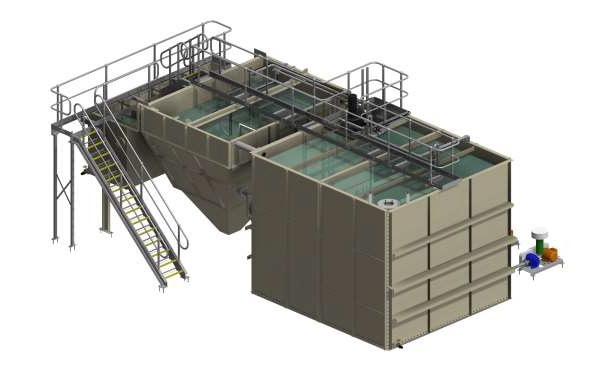

Roadtrain® - Rectangular Design

- Extended aeration process. Can be configured for nutrient removal

- Optional bolted design to allow flat packing and shipment to very remote locations.

- Simple onsite installation

- High quality effluent discharge with optional tertiary systems for reuse

- Remote monitoring with HyConnect®

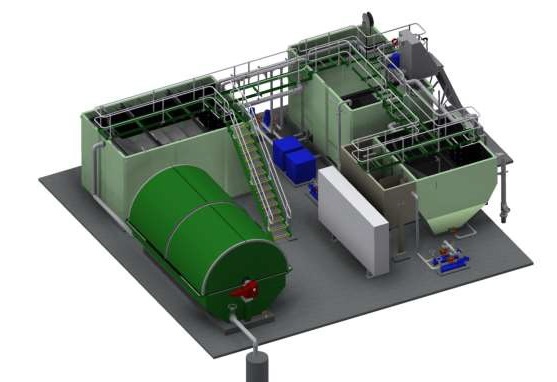

Roadtrain® - Circular Design

- Extended aeration process. Can be configured as MLE process for nutrient removal

- High Capacities up to 5000EP

- Optional bolted design to allow flat packing and shipment to very remote locations.

- Simple bolted connection onsite

- High quality effluent discharge with optional tertiary systems for reuse

- Remote monitoring with HyConnect

Roadtrain® - Rotating Biological Contactor Design

- Ideally suited for unattended sites in remote locations

- Inclusive of primary and secondary clarification steps

- Can be configured for nutrient removal

- High quality discharge with optional tertiary treatment

- Low operating costs

Inlet Works Screening

Raw sewage is either screened using a static screen, or an automatic mechanical screen.

Grit removal can be incorporated in the mechanical screen package

Aeration Systems

Typically fine or medium bubble submerged diffusers.

Sludge Management

Typically pumped to a storage tank for offsite disposal, or to drying beds for dewatering and drying.

Options for digestion and mechanical dewatering are also available.

Water Reuse

Tertiary treatment with sand or membrane filtration can allow reuse for fire fighting, toilet flushing or irrigation

SECTION: 1 SPECIFICATION

- Inlet Screen: Stainless steel

- Balance Tank: Painted steel tanks

- Reactor Tanks: Painted steel tanks

- Pipework: PVC/ABS

- D iff users: Stainless steel/PVC

- Clarifier Internals: Stainless steel wetted parts

- Sludge Drying Beds: Concrete