- Home

- Companies

- Premier Tech

- Products

- Premier Tech - Model VPC & VPK Series - ...

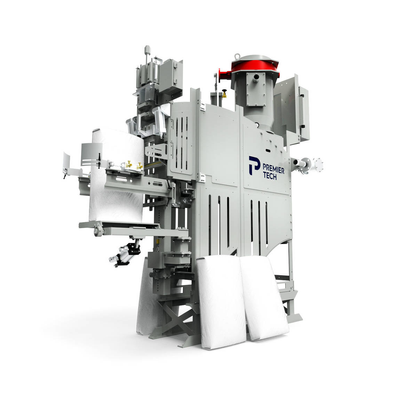

Premier Tech - Model VPC & VPK Series -Packer with Integrated Ultrasonic Valve Bag Sealer

The VPC & VPK Series (former CleanPak) with integrated ultrasonic valve bag sealer ensure highly sanitary operation while handling dusty products by closing the bag`s valve before it is moved from its original filling position.

These ultrasonic sealers also feature an inflatable filling tube collar and swirl air blast tube clean-out, with active dust collection throughout the cycle. The sealed valve eliminates any dust puff that may be released by filled bags when discharged onto the conveyor.

The VPC & VPK ultrasonic sealers are rigidly mounted to the frame of our Air packer or Impeller packer, providing a state-of-the-art solution that accurately and cleanly seals your valve bags. With their cutting-edge technology, you can be sure that your bagging process is efficient and precise.

- Speed: Up to 4 bags per minute

- Bag types: Valve

- Bag materials: Paper

Accuracy

- Closes bag valve before bag is moved from filling position, ensuring clean operation and preventing product contamination

- Sealed bags do not leak during conveying, stacking, or shipping

Design quality

- Easy to use as a retrofit, mounted to Premier Tech’s Air and Impeller packer

- Designed for dusty environments to minimize product build-up

- Laser-cut and bolted frame

- Plumbing and wiring internally routed and protected by steel framework

Performance

- Produces effective seals, protecting the product from contamination

- Rugged PINSONIC type ultrasonic components

- BOSS (Bag On Spout Sensing): laser detectors ensure that the bag is properly installed on fill spout before machine is started

- Horizontal (gusset) or vertical (butt) discharge

- Touchscreen operator control with user-friendly interface

- Built for environments prone to dust explosion

- Stainless steel construction

- Metal detector integration

- Advanced seal inspection technology

- Typical footprint 90.25” L x 21.5” W x 80” H (2290 mm x 546 mm x 2032 mm)

- Air consumption10 scfm @ 80psig (clean and dry)