Panda Pipe - Model SSAW -Pipe

SSAW pipes are often utilized for diameters greater than 20 inches NPS (Outside Diameter). The spiral welded pipe has a circular cross-section and is formed using double wire-double-sided submerged arc welding, an ae/a technique. This material has excellent strength, low porosity, and low permeability, making it suitable for oil and natural gas. The hydrostatic test, tensile strength, and cold bending performance of the weld joint must conform to the specifications for the SSAW pipe.

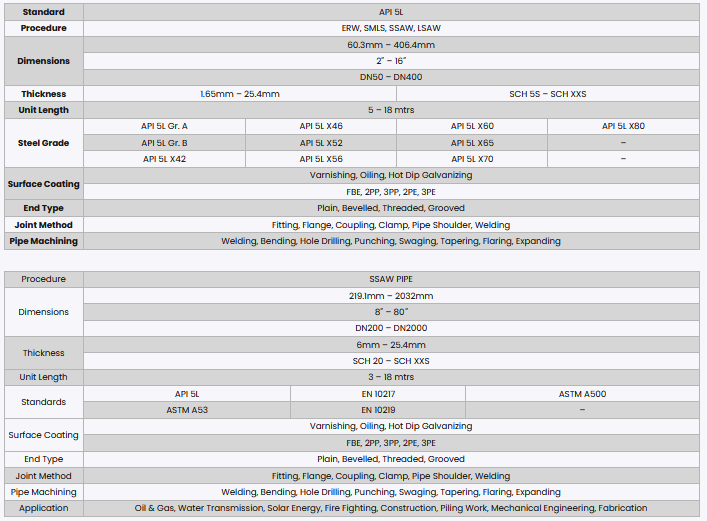

Our SSAW pipes are produced using the Spiral Submerged Arc Welding procedure, ensuring high strength and durability. Available in various dimensions and steel grades, these pipes meet stringent production standards. The surface coatings applied provide additional protection against environmental factors. We offer different end types and joint methods, all machined to precision. SSAW pipes are commonly used in applications like water supply, construction, and oil and gas industries.

What is SSAW Pipes Used for?

Due to the fact that SSAW pipe can withstand a significant amount of pressure, it is utilized in a wide variety of construction applications. Piling, structural applications, water pipelines, slurry pipelines, dredge pipelines, and other types of pipelines are some of the uses for SSAW pipe.

- Oil & Gas

- Construction

- Water Transmission

- Piling Work

- Steel Fabrication

- Mechanical Engineering

What is the difference between SSAW pipe and LSAW pipe?

SSAW Pipe and LSAW Pipe are both SAW (submerged arc welded) pipe types often utilized for oil and gas transportation. The process through which they are welded distinguishes them. Steel coils are spirally welded, like a helix, in SSAW, such that the coil (strip) takes on the shape of a pipe. The welding of LSAW pipes is longitudinal, which means that steel (hot-rolled coil plate) is rolled into a pipe and the seam is longitudinally welded.

SSAW Pipe

- Low cost

- Welding Direction: Spiral direction

- production efficiency:High efficiency

- Outer Diameter: 20 inch to 100 inch

- Main Application: Construction

- Thickness Tolerance: Relatively accurate

- Geometry accuracy: Low

LSAW Pipe

- Relatively expensive in price

- Welding Direction: longitudinal direction

- production efficiency:Low Efficiency

- Outer Diameter: 16 inch to 60 inch

- Main Application: medium/high pressure

- Thickness Tolerance: Relatively accurate

- Geometry accuracy: High