chengdu purui polymer engineering co.,ltdPurui Plastic & Rubber Machinery Co., Ltd

Purui - Model ML -PE Granule Water Ring Pelletizing Line Machine

PE granule Water Ring Pelletizing Line for PP PE LDPE LLDE BOPP Waste Agricultural Film.

Most popular related searches

pellet plant

BOPP film

granulator

pelletizer

pelletizing

water ring granulation

granulation machine

screw extruder

temperature meter

material crushing

Quick Detail for PE Granulator for PP PE LDPE LLDE BOPP waste agricultural film

- FREE FOR SOME ELECTRIC PARTS:

- TEMPERATURE METER

- AC CONTATOR

- BUTTON

- THERMOCOUPLE

Material types: pp film, pe film, ldpe film, hdpe film, lldpe film, bopp film,waste agricultural film

- CE certificate

- CAS identification

- Lower power consume

- More stable output

- Smooth & full pellets

Description for PP PE Granulator for PP PE LDPE LLDE BOPP waste agricultural film

Features of PP PE Granulator for PP PE LDPE LLDE BOPP waste agricultural film:

High efficiency

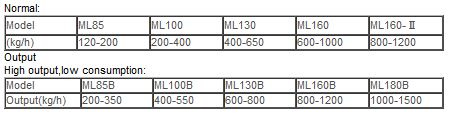

Compared with the primary design, the output of PURUI second generation film granulator machine has been increased 20%.

Low power consumption

The power consumption reduced 15% compared with the primary design,.

Highly automatically,

Only 2 people for one production line.

Applications of PP PE Granulator :

Features of PP PE Granulator for PP PE LDPE LLDE BOPP waste agricultural film:

High efficiency

Compared with the primary design, the output of PURUI second generation film granulator machine has been increased 20%.

Low power consumption

The power consumption reduced 15% compared with the primary design,.

Highly automatically,

Only 2 people for one production line.

Applications of PP PE Granulator :

- Applicable plastic materials: all kinds of film,such as PE, HDPE, LDPE,PP, BOPP etc

- Material shapes: film, crushed material

- Material types: rolls, loose, bundled

- Material comes from offcut, defective film and washed film.

- Note: depending on different material properties, various downstream equipments are needed.

How it works

①Feeding is automatic according to customer requirements.In the patented ②cutter compactor the material is cut,mixed,heated,dried,densified and buffered.

The tangentially connected extruder is filled continuously.In the ③ extruder screw the material is extruded.

In the ④ degassing zone: the air and water etc is volatilized .The material is extruded to the die ⑤.and ⑥ pelletizer.

- skillful manufacture

- sophisticated technology

- finely processed

- Latest technology

- professional design

- rational construction

- excellent quality

- durable in use

- dependable performanc

- easy and simple to handle

- selling well all over the world and win warm praise from customers

- excellent technical engineer team

- one year quality guarantee