- Home

- Companies

- Zhangjiagang Boxin Machinery Co., Ltd.

- Products

- Boxin - Model 500-5000kg/h - PET Bottle ...

Boxin - Model 500-5000kg/h -PET Bottle Washing Machine

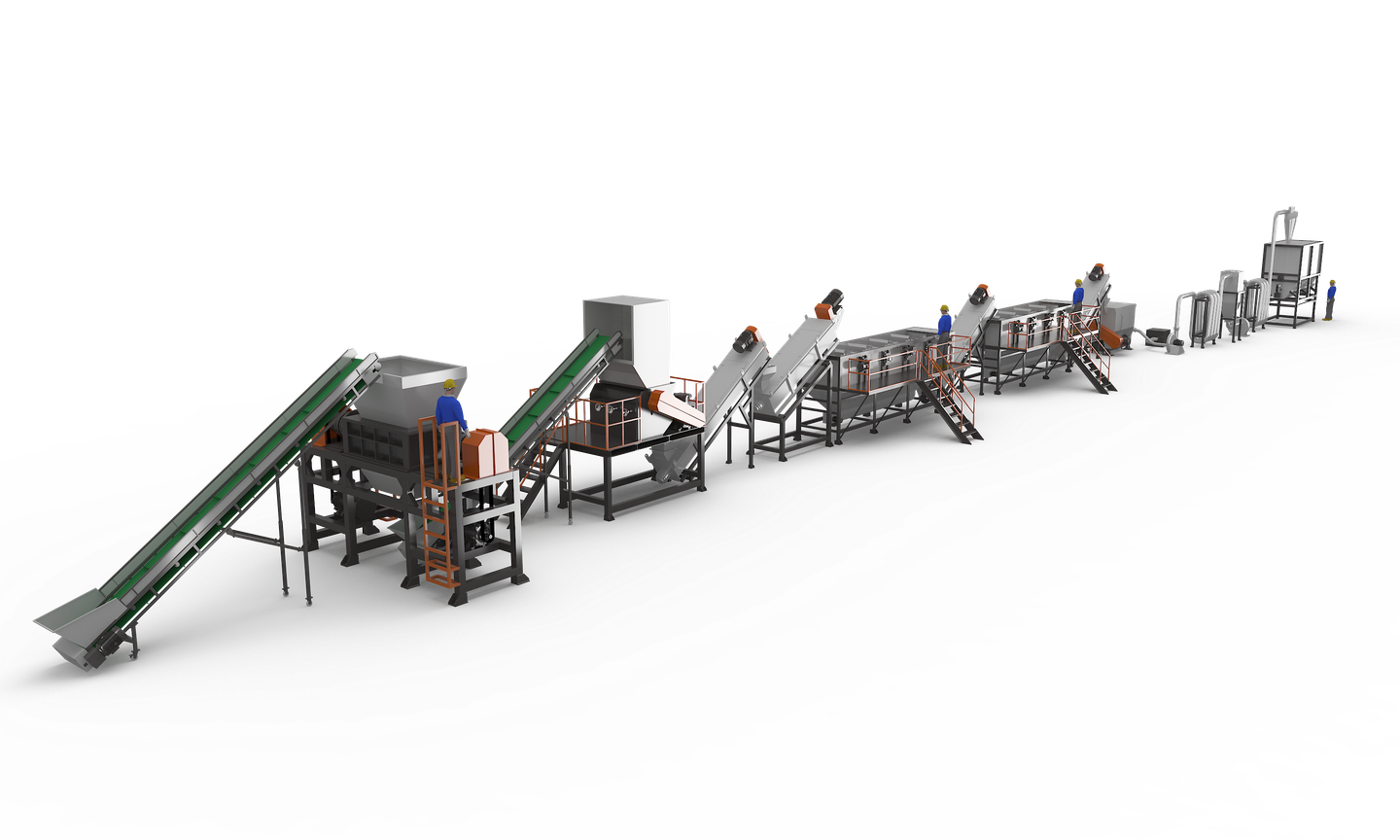

Our pet bottle recycling machine can convert dirty mineral water, pet plastic bottles, coke bottles, plastic milk bottles, and other waste PET plastic into clean PET bottle flakes. The pet recycling machine is fully automatic, and the washing process includes conveying, de-labeling, crushing, washing, drying, color sorting, and bagging. An electric control cabinet controls the whole recycling line.

Pet recycling machines are Advanced equipment in the circular economy of washing and recycling PET waste plastic. Through the PET bottles recycling machine, the washed and recycled plastic flakes can be fed into a granulator to be made into pellets, e.g., to make new PET bottles or other plastic products.

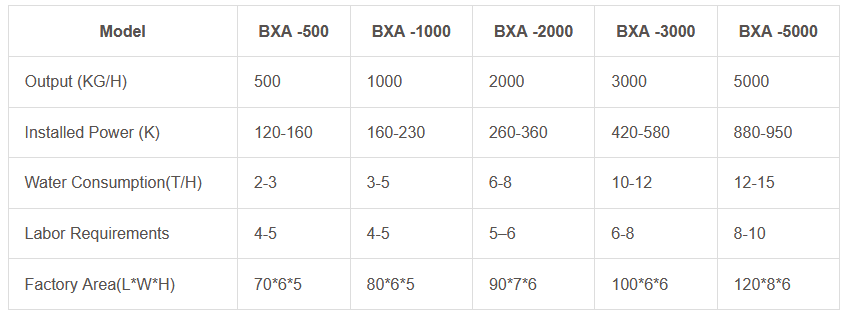

We offer a standard plastic bottle recycling washing line from 500-5000 kg/h. Still, of course, as a Chinese supplier of washing and recycling machines for fiber to food grade PET bottles with 20 years of experience in recycling, boxing has a wide range of solutions for different levels of contaminated materials, such as multi-stage washing, additional color sorting equipment, metal removers, and so on. Depending on the plastic materials, line requirements, quality of the finished product, and budget control,

We offer decontamination solutions to meet your needs.

- Metal removal washer: Improve the quality of finished products by magnetically adsorbing small metal objects

- Color sorter: Through advanced optical capabilities, it automatically sorts bottles of different colors, reducing labor and improving the quality of finished products.

- Label suction machine: uses a fan to suck in small label fragments and dust to improve the quality of finished products

- Multi-stage cleaning: specially designed for bottles with higher contamination levels

- Water treatment system: Reduce energy consumption and reduce secondary discharge of wastewater that pollutes the environment

Variety of output

- 500-5000kg/h standard fully automatic pet recycling machine.

Excellent finished product quality

- Up to 98% label removal rate

- After entering the high-speed dehydrator, the dehydration rate of bottle flakes can reach 99%

- Increased equipment, finished product up to food grade

Self-developed crushing system

- Heavy-duty claw rotor, high-quality alloy steel welded structure, stress-relieved and dynamically balanced, solid, and stable in operation. The rotor has a V-shaped installation angle and an X-shaped cutting shape. A speed-regulating wheel can be installed on the extended shaft of the rotor.

Save water resources

- A water treatment system was added to reuse wastewater, and the water consumption per ton of the PET recycling machine was reduced to less than 1.5 liters.

Customized solutions

- Based on the material contamination level and finished product requirements provided by the customer, we add or reduce different small equipment so that the customer can purchase the most suitable PET recycling machine at the most friendly price.