- Home

- Companies

- Neue Herbold Maschinen-und Anlagenbau ...

- Products

- Neue Herbold - Model HZR Series - Pipe ...

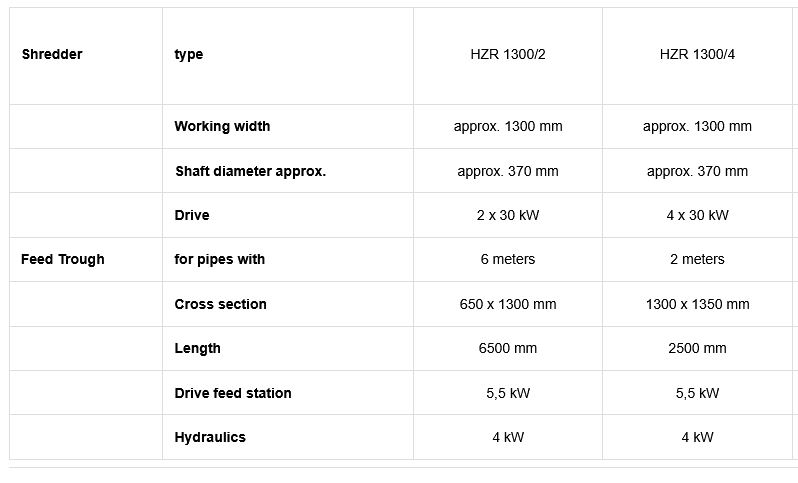

Neue Herbold - Model HZR Series -Pipe Shredder

The capacity of the pipe shredder depends on the impact strength, the wall thickness of the tubes and the screen perforation. The output per working hour is up to 3 tons with a perfect state of cutting tools. The feed of the pipe shredder is from the side by a feeding tub in front of the rotor.

An automatic and load-dependent controlled feeding system ensures the supply of the pipes to the shredder shafts. Here, the press ram is driven by a gear motor and via a cable.

The housing of the pipe shredder comprises a stable fabricated and well welded steel construction. The housing has been provided with outwardly arranged consoles to accommodate the bearings, motors, gears and couplings.

The cutting tools are made of profiled rotors to use the cutting crowns in a V-shaped seat and two-sided usable cutting crowns and counter knifes. The rotor shafts are stored in the robust double roller bearings.

The control is via a Siemens SIMATIC S7 touch–screen panel.

The NEUE HERBOLD pipe shredders type HZR are specially developed for effective pre-crushing of lumps and impact-resistant and thick-walled tubes with diameters up to 1200 mm.

Usually the HZR is followed by a granulator. These shreds the material into a fine material.

Supported by the downstream granulator the HZR reduces energy consumption by 20% – 50%, compared to the single-stage crushing. The tools of the HZR have a long durability, a key prerequisite for high profitability.

- reduced energy costs by between 20% – 50%.

- long lifetime of the tools.

- very good cost efficienc