- Home

- Companies

- Breivoll Inspection Technologies (BIT)

- Products

- Pipescanner - Inspection Device

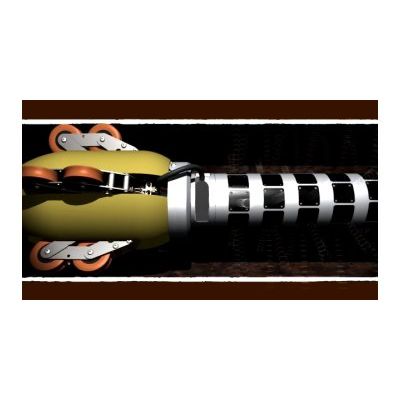

Pipescanner - Inspection Device

An inspection device, called a ‘Pipescanner’ is fed into the pipe. The device is equipped with 64 ultrasound transducers, located for coverage of the entire pipe wall in 360 degrees. During the data acquisition process the Pipescanner is pulled through the water filled pipe to cover the whole pipeline. The Pipescanner is pulled through the pipe using a Kevlar-armoured cable, which also provides electrical power to the Pipescanner and transfers the collected data to the mobile inspection unit. The data are stored and then taken to our head office for further analysis and production of condition reports.

Inspection results are verified through laboratory measurements, field tests and verification studies carried out by Det Norske Veritas. The images below illustrate the results from one of the verification tests. A corroded pipe was excavated, sand blasted and compared with optical measurement results performed by SINTEF. The sand blasting process was carried out so that only the solid material of the pipe remained.

The Pipescanner results are on the left, optical high resolution results in the centre and a photographic image of the sandblasted pipe on the right. The Pipescanner results indicate the same corroded areas as seen on the two other plots.

Our inspection method has been developed in close cooperation with leading international and Norwegian research and development organisations.

The inspection method employed by Breivoll Inspection Technologies (BIT) is based on patented technology, licensed from Det Norske Veritas (DNV) to BIT. DNV has also contributed with algorithm development and signal processing. Other key partners are Data Respons (electronics), PCT - Scotland (sensor/transducer technology), Tromsø University, Norut, Jupiter Systempartner (data systems) and Beck Engineering (mechanics).

We attach high value to further improvement of our inspection method. We believe it is important to always supply results based on the best available technology. We also want to meet the challenging demands regarding product and operations requirements from the market. Therefore, we continue to invest heavily in high level research and development projects.

The Norwegian Research Council awarded Norway’s first Industrial PhD grant to Breivoll Inspection Technologies for our research project related to innovative methods for the inspection of water pipes.