Sera GmbH

sera - Piston Diaphragm Pumps

FromSera GmbH

sera Piston Diaphragm Pumps are leak-free oscillating displacement pumps designed for the dosing of volumes up to 1500 l/h and up to maximum 50 bar - depending on flow capacity. They are an ideal combination of the high supply pressure of a piston pump and the perfect leak-proof diaphragm pump.

Most popular related searches

piston diaphragm pump

diaphragm pump

piston pump

pressure relief valve

safety system

integrated safety

relief valve

ball valve

displacement pump

integrity monitoring

Field of application:

- Flow free mediums with:

- aggressive

- abrasive

- viscous

- radioactive

- flammable

- odorous

- or toxic characteristics

Performance characteristics:

- Leakage free

- Highest dosing accuracy

- Dry run safety

- High quality materials

- Continuous operation with minimum maintenance

- Long operating life

- Easy to operate

- Integrated safety device against overpressure

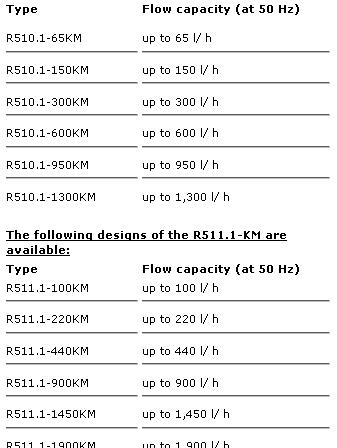

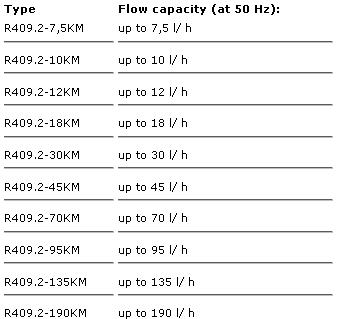

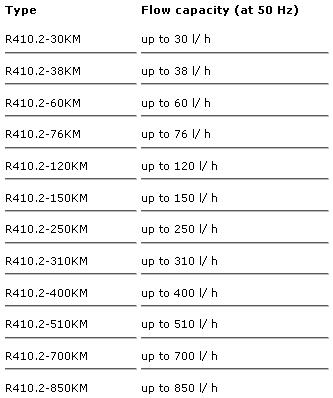

The following designs of sera piston diaphragm pumps are available:

R409.2-...KM (from 7,5 l/h up to 190 l/h)

R410.2-...KM (from 30 l/h up to 850 l/h)

R511.1-...KM (from 100 l/h up to 1,900 l/h)

A suitable material is available for each dosing medium!

Appropriate materials are selected for single and double

valves, valve balls, valve seals and diaphragms.

Three-phase drive motor

- High operational safety by multi-layer diaphragm technology

- Indication of diaphragm condition by integrated diaphragm rupture monitoring (visual as standard design / electrical available as option)

- Integral overpressure safety device

- Excellent priming characteristics without additional equipment

- Type examination for ATEX-range guarantees certified safety

- Wide range of application by an extensive programme of material combinations and accessories

- Wide range of applications thanks to a performance between 65 l/h and 1,900 l/h with counter pressures of up to 220 bar

- Exact flow respectively dosing rates by variable eccentric drives with a harmonic motion sequence

- High operating reliability thanks to a hydraulically driven multi-layer diaphragm made of high-quality material

- Display of the diaphragm state by an integrated diaphragm monitoring (optically for standard/ electrical option)

- Safe against overpressure by an internal pressure relief valve

- Wide field of applications thanks to extensive accessories as well as an optional design for explosion-proof applications following API Standard 674/675