Kuttner Martin - Plants for Treatment of Sewage Sludge

We plan and manufacture plants for the environmentally friendly treatment of sewage sludge. In doing so, we also make usable the vital raw material of phosphorus contained in the sludge and hence act in line with a sustainable circular economy. Plants based on a stationary fluidized-bed incineration system are ideally suited for treating fuel with a low heating value such as sewage sludge without adding auxiliary fuels. This fluidized-bed technology has been established for many decades already. KÜTTNER built and successfully deployed first plants for the regeneration of foundry sand in the 1990s already. Adapting the existing know-how and the experience gained with handling low-calorific fuel in the environmental engineering sector lead to sewage sludge combustion based on fluidized-bed technology.

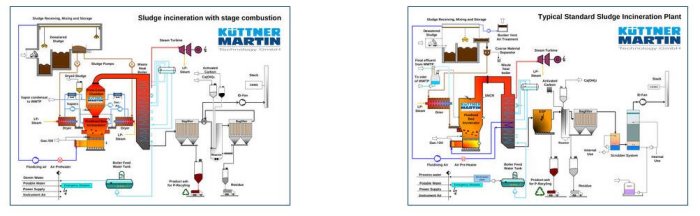

The fluidized bed is the core component of the plant. We consider the concept for the overall plant when designing the fluidized-bed unit. The focus is on complying with environmental standards, high plant availability, a high degree of automation and the energy and media efficiency. Since the properties of sewage sludge are very varied, the fluidized bed must be able to satisfy these requirements, even across a wide range of fuel characteristics. For this purpose, we offer the fluidized-bed technology with and without staged combustion air supply. In combination with a top-fitted post-combustion chamber, secondary air can very effectively be supplied in a staged fashion.

Along with the demands made on the fluidized-bed technology, there are also very specific requirements for the entire system, the sludge transport unit, the thermal predrying equipment, for recovering heat in a steam or thermal oil boiler and for the flue gas cleaning system. In excess of 80 % of the thermal output from the fuel can be made utilizable within the process. After the thermal energy recovered from combustion was used for drying the sewage sludge and preheating the combustion air, it can be made available for additional applications such as for generating electricity and for process and district heating. In addition to a fluidized-bed incineration system provided by KMT, the design of the flue gas cleaning system is essential to later operate a plant that is both low in emissions and economical. When designing an appropriate cleaning system, the characteristics of sewage sludge (high sulphur and mercury contents) must be taken into account. Layout planning and considering the site-specific framework conditions also play an important role in the design of the plant. Concepts for individual components, subsystems and even turnkey projects are developed in close cooperation with the customer. The approach can be implemented both for new plants on greenfield sites as well as for the integration into an existing infrastructure. For all of these key tasks, our customers today turn to KÜTTNER MARTIN Technology GmbH where they find the experts with decades of professional experience.