- Home

- Companies

- Suzhou Jono Environmental Technology ...

- Products

- JONO - Model 1FAX2003A - Plastic, ...

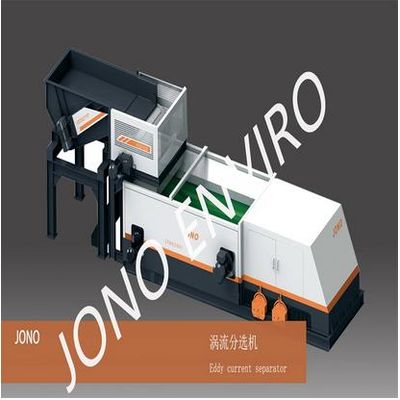

JONO - Model 1FAX2003A -Plastic, Aluminium Eddy Current Separator - Metal Sorting Machine

The Eddy Current Separator (ECS) is an advanced metal sorting unit that is capable of separating non-ferrous metals such as aluminium,copper,brass,alloy from dry recyclables. JONO eddy current separator can produce higher purity and increased yield of better separation of aluminum cans from PET plastic beverage containers.Nowadays it became the most economical beverage bottle sorting and recycling equipment.

- After-sales Service: Instruction for Commissioning and Maintenance

- Warranty: 1 Year

- Type: Eddy Current Seperator

- Object: MSW/Industrial Waste/Construction Waste..

- Drive: Electric

- Crushing Degree: mechanical sorting

- Customization: Available

Basic Info.

- Model NO.: 1FAX2003A

- Crushing Style: mechanical sorting

- Principle: material size

- Cutter Material: Hard Alloy

- Finished Surface: Outer Surface Process

- Compressive Strength (For Crushing); >300MPA

- Tongs′ Features: Adjustable Tongs

- Lead Time: 1-3 Month

- Customize: Welcome

- Color: White/Orange/Blue/Black/Customize

- Weight: 3100kg

- Transport Package: Container

- Specification: 1FAX2003A

- Trademark: Jono

- Origin: Jiangsu, China

- HS Code: 8464909000

- Production Capacity: 10/Month

The principle of the eddy current separator is to use the magnetic field of the electric conductor transform to produce the force and to separate the conductor from the non-conductor. Magnetic roller is installed on the high-speed belt discharging end, with high speed rotary motion during operation, the material in the high-speed belt were uniformly distributed in the surface of the belt, when the metal into the magnetic roller magnetic field, by cutting the magnetic induction line to generate force ,kick the non-ferrous metal into specific area. Remaining materials will fall into the other area.

The eddy current separate can sort out non-ferrous metals such as cans, pull rings, copper and other plastic, fabric, wood bamboo, masonry and so on, which can reduce the generation of dioxin and re-use high-value recyclable resources.

- Quick maintenance check due to a window installed on the maintenance door .

- Minimum maintenance work due to anti-winding design.

- Efficient operation with electrical drive.

- Save space due to compact construction design.

- Optional frequency converter.

- Model: 1FAX2003A

- Eddy current magnetic roll motor: 7.5KW,ABB

- Belt gear motor: 4KW,SEW

- Belt maximum velocity: 3 m/s

- Capacity: 20 m³/h

- Belt width: B=2000mm

- Machine Size: 8735*3115*3109mm

- Weight: 5250kg

- Including : 2 sets of Mitsubishi frequency converter,1 set of Siemens PLC, etc