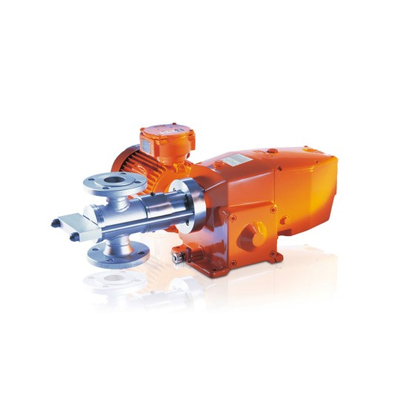

ProMinent - Model Orlita DR -Plunger Metering Pump

Capacity range of single-head pump: 0 – 273 l/h, 400 – 76 bar. The plunger metering pump ORLITA DR does not need valves and can therefore be operated within a broad stroke rate range. It is therefore suitable for use with high-viscosity and extremely high-viscosity media of up to 106 mPas within a wide temperature range of -30 °C to +200 °C.

For the precise metering of high-viscosity and extremely high-viscosity media even containing solid fractions

ORLITA DR plunger metering pumps (DR 15 to DR 150) are special pumps for high-viscosity and extremely high-viscosity media, which can also contain solids. The pump can be operated within a broad stroke rate range due to its operation without valves.

Optimum adaptation to processes with high-viscosity and extremely high-viscosity media, even those containing solid fractions:

- Low-wear and precise operation even at high pressures thanks to the rotary piston with abrasion-resistant / wear-resistant surface coating

- Valve-free operation guarantees a broad stroke rate range

- Wide range of uses: Operating pressure of up to 400 bar, temperature range of -30°C to +200°C

- Pumping direction can be selected depending on the fitting position of the piston

- A reverse suction effect can be set in a continuously variable manner by rotating the pump head around its longitudinal axis

- Power end configuration ideal for installation in any position (vertical or horizontal)

The following list of applications are general examples of generally suitable applications for this product. Please contact your local sales representative to talk about the applicable use of this product in your specific case / environment.

- Metering of high-viscosity and extremely high-viscosity media containing solid fractions.

- DR 15 - stroke length: 0-15 mm, rod force: 1800 N

- DR 150 - stroke length: 0-32 mm, rod force: 15000 N

- Stroke length adjustment range: 0 – 100% in operation and idle

- Stroke length adjustment: manually using manual adjustment wheel and scaled display (optionally with electric actuator or control drive)

- The dosing precision is better than ± 0.5 % within the 10 – 100% stroke length range under defined conditions and with correct installation

- Wetted materials: Stainless steel, special designs are available on request

- A wide range of power end/drive versions is available: Three-phase standard AC motors, motors for use in areas at risk from explosion and different flange designs for use in customer-specific motors

- Degree of protection: IP 55

- Temperature range -30°C to +200°C

- The play between the piston and cylinder responsible for the sealing effect is selected depending on the viscosity

- Turret on the rear head end, either designed as a circular collecting vessel for leaks or exposed to a sealing medium

- The turret is sealed by elastomer lip sealing rings