- Home

- Companies

- Compressed Gas Technologies Inc.

- Products

- PMNG - Model Economy Series - Membrane ...

PMNG - Model Economy Series -Membrane Nitrogen Generators

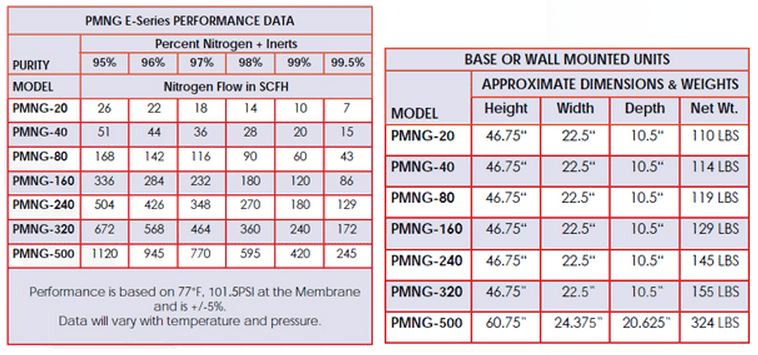

PMNG `E` Series nitrogen generators use patented membrane technology to produce an uninterrrupted supply of gaseous nitrogen, on site. This compact system is ideally suited for low-flow applications that presently employ high-pressure gas cylinders or dewars of nitrogen. With PMNG Membrane Nitrogen Generators, the inconvenience of gas cylinders and liquid dewars is eliminated. Nitrogen is generated at your location, continuously and reliably, requiring only a supply of compressed air. CGT INC. membrane technology works by filtering oxygen from a stream of compressed, dry air via hundreds of thousands of hollow, polymeric fibers - each about the diameter of a human hair - to produce gaseous nitrogen. The flow and purity of the nitrogen are at your control, assuring the perfect match to your nitrogen requirements. And, the automated PMNG Membrane Nitrogen Generators system virtually operates itself without requiring the attention of an operator.

- Food packaging

- Chemical Blanketing

- Modified Atmospheric Packaging

- Coffee Packaging

- Pharmaceuticals

- LCMS

- Laser Cutting - beam purge

- Plasma Cutting Systems

- Quality air pre-treatment filtration system

- Simple, reliable flow control system with manual purity and flow adjustment

- Nitrogen purity adjustable from 95 - 99.9%

- Nitrogen flows from 15 - 2000 scfh

- Simple, manual process control

- Air supply and nitrogen storage pressure gauges

- Plug & play operation

- Gaseous nitrogen on demand

- No cylinder storing, monitoring, handling, demurrage charges, or delivery concerns

- Low cost, reliable

- No shortfalls or overages

- Silent, unattended operation

- Small footprint - allows site flexibility

- Floor or wall mount

- Minimal maintenance, easy to service

- No electricity, no moving parts

Inside the PMNG nitrogen generation unit, the first item the compressed air comes in contact with is the 4-Step filtration system, which utilizes a combination of particulate, coalescing and carbon adsorption technologies.

After the filtration system the oil carry-over in the compressed air is expected to be in the 3 parts per billion range, with maximum solid particle size .3 micron. All filters are fitted with automatic condensate drains. Some high flow units are fitted with an air circulation heater and controls, and are installed in the air stream before the nitrogen membrane(s) but after the final filter and pressure regulator. This heater maintains a constant temperature of compressed air to the membranes enhancing stability and performance.

After the compressed air passes the final filter the air then enters the nitrogen membrane module(s) where the air separation occurs. Membrane technology works by filtering oxygen from the dry compressed air stream via hundreds of thousands of hollow, polymeric fibers each the diameter of a human hair to produce gaseous nitrogen.

The nitrogen membrane module(s) are connected in parallel. Depending on the desired flow and purity required will determine how many membrane modules will be utilized. After the air passes through the membrane bundle(s) it is essentially nitrogen plus trace amounts of inert gasses and the specified oxygen content. A flow/ purity control valve will maintain the flow and purity requested by the customer. Waste gas will be vented to atmosphere. PMNG membrane nitrogen generators have many available options;