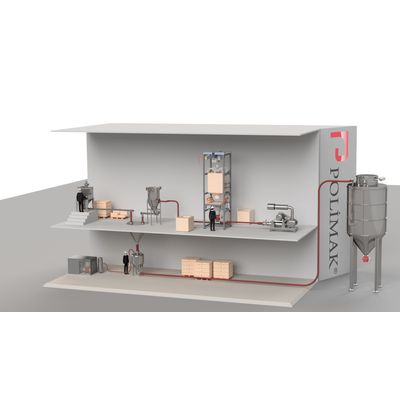

The design, production and installation of pneumatic conveying systems for bulk materials require a great deal of know-how and long years of experience. Simple installation, low maintenance need, long years of problem-free service and endurance for harsh environments are key features of quality pneumatic conveying systems. Polimak brings pneumatic conveying solutions and expertise to a variety of industries including chemicals, food, plastics and cement. A well designed pneumatic conveying system is a practical and cost-effective method of transporting dry bulk materials from one point to another.

Pneumatic Conveying Systems

Pneumatic conveying systems are broadly used throughout bulk material handling industries to move dry bulk materials through a facility. They move the bulk material in a pipeline generally with air being used as a conveying agent. When it comes to utilising pneumatic conveying systems to transport dry bulk materials, facility owners find themselves in a position to of needing to make a choice between pressure conveying or vacuum conveying. In other operations, a combination of both, vacuum and pressure conveying systems may be the best solution. Ultimately, Polimak experts will have to consider what is feasible given the available resources and suggest which method will best suit the transportation of the bulk material.

There are several ways to pneumatically transport dry bulk materials and the key difference in each method is the conveying phase. Conveying phases are modes of how dry bulk materials being conveyed through a conveying pipe. Pneumatic conveying phase mode can be categorised into two, the dilute phase and the dense phase.

Dilute phase pneumatic conveying systems, also known as lean phase conveying systems, involve the transportation of dry bulk materials at velocities above the saltation velocity. These systems generally use air entry pressures below 1bar to move dry bulk materials through conveying pipelines at relatively high velocities. Bulk material particulates are wholly suspended within the airstream throughout the conveying pipe in dilute conveying systems. The material transfer within the system is described as low pressure high velocity, hence the name “low pressure systems”. The particle velocity is paramount in these systems because it affects the material end product, very low velocity may result in the material collapsing to the bottom of the pipe from the airstream and very high velocity may cause particle-to-particle collision and particle-to-wall collision resulting into bulk material degradation. The two methods that can be performed are dilute phase pressure conveying and dilute phase vacuum conveying.

Dilute phase conveying systems are the most common pneumatic conveying systems used in many bulk material handling industries to transport bulk solids. These systems are ideal for transporting non-abrasive bulk materials, products with low bulk density and bulk materials that are hard to break. Some of the dry bulk materials that can be processed using dilute phase pneumatic coveying systems include sugar, flours, pellets, chemicals, polymers (resins and compounds), calcium carbonate, cement and coal dust.